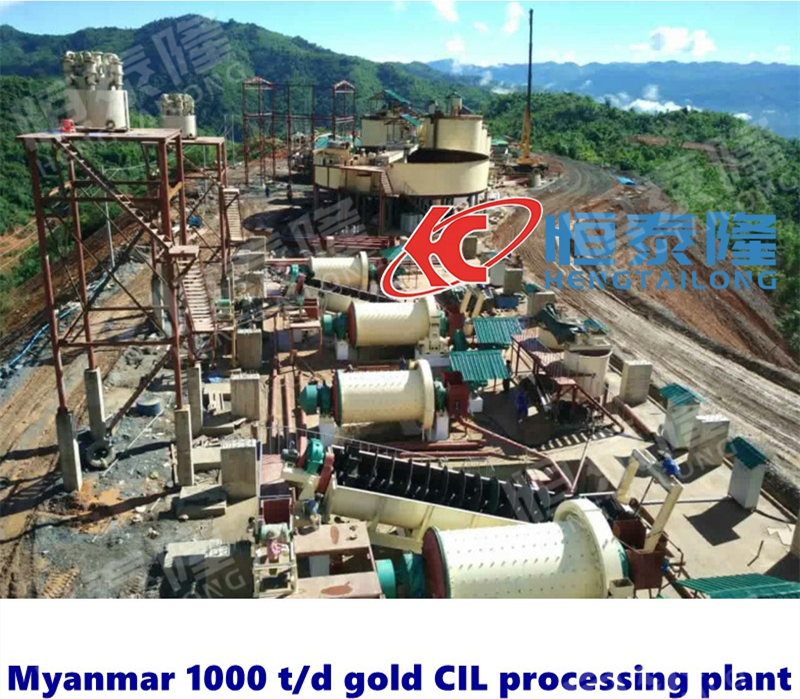

Gold ore Mining Separation Beneficiation Cip Gold Processing Plant

In Gold CIL (carbon in leach) Processing Plant, activated carbon acts like a sponge to aurocyanide and other complex ions in solution.Hard carbon particles (much larger than the ore particle sizes) can be mixed with the ore and cyanide solution mixture.The gold cyanide complex is adsorbed onto the carbon until it comes to an equilibrium with the gold in solution.Because the carbon particles are much larger than the ore particles, the coarse carbon can then be separated from the slurry by screening using a wire mesh.

Widely Used Rock Gold Solution1:

1.The principle of more crushing and less grinding is achieved. The ore particle size is crushed to 10-12mm or less by three-stage-crushing with singlec losed circuit stage process to reduce the load of the grinding system.2.Use New flotation reagents The fiotation results can be greatly improved by using compound collectors instead of traditional xanthate collector.3.Pneumatic flotation machine is used to ensure the flotation effect Pneumatic fiotation machine is adopted to obtain good ore beneficiation indicators.4.High degree of automation Through the automatic control system, the whole process of ore beneficiation is under monitoring,so the production line can be large -scale, automatic and easy to manage and control.

Widely Used Rock Gold Solution2:

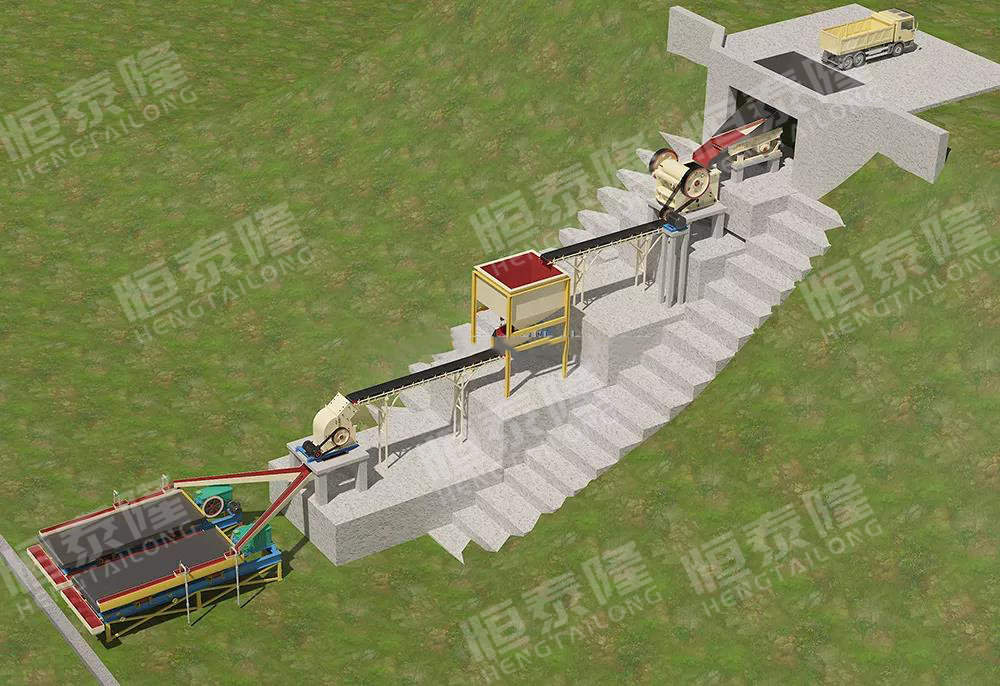

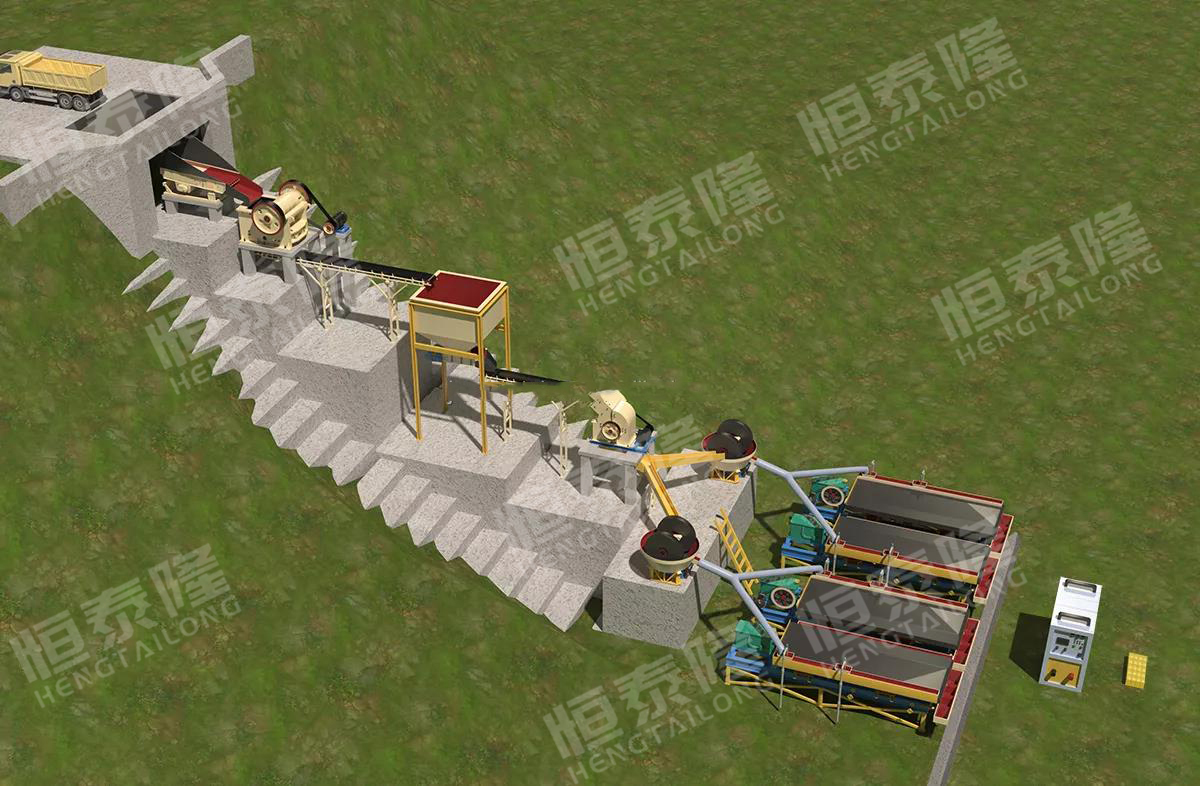

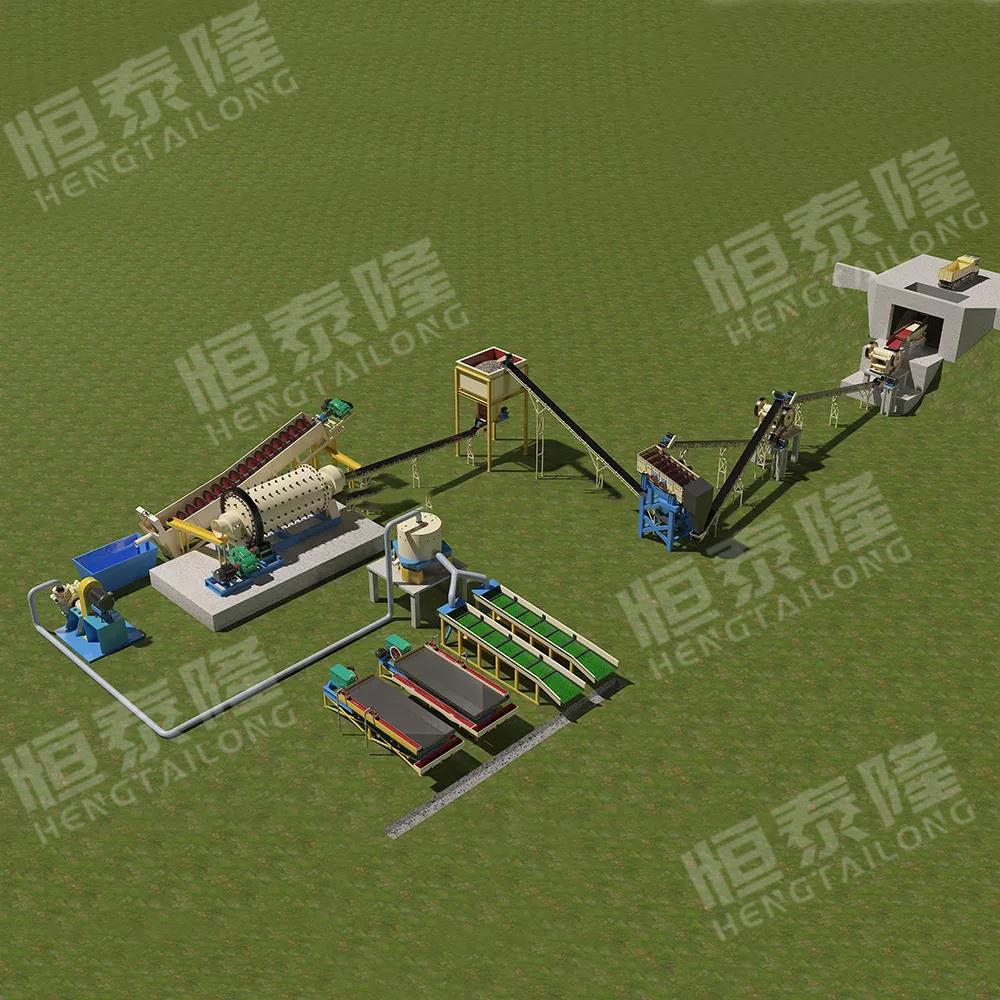

Hard-Rock Gold Mining Via Ball Mill + Shaking Tables

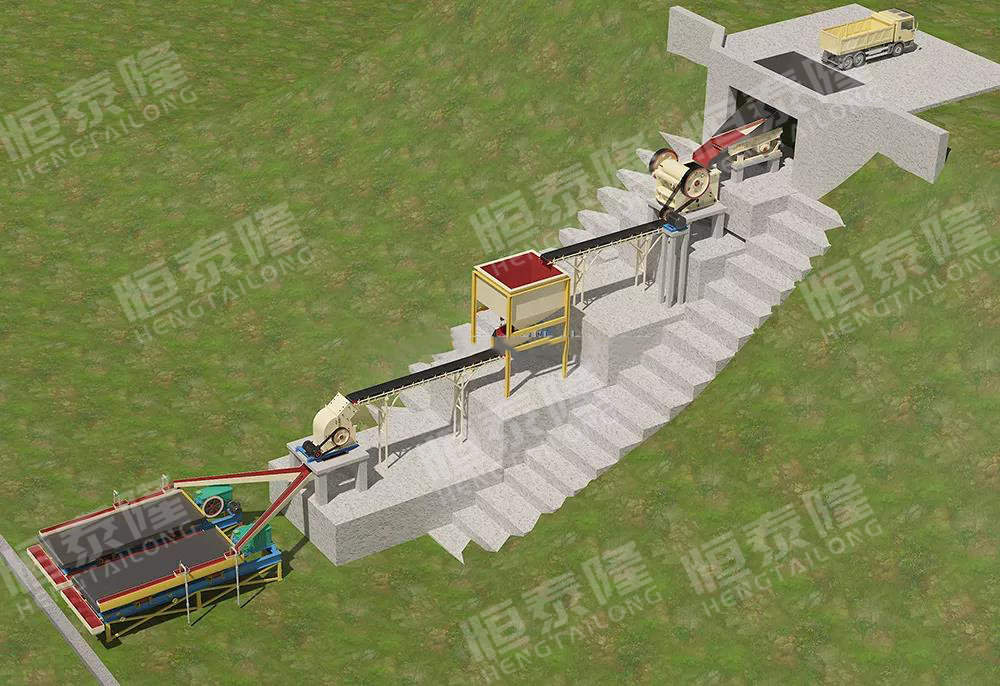

1.Loader or Excavator feed raw ore into the hopper;2.Vibrating feeder feed primary jaw crusher; primary jaw crusher is to crush big stone to medium size. 3.Output of primary crusher sent to fine jaw crusher by belt conveyor; fine jaw crusher is to crush medium sized stone to small size.4.Output of fine jaw crusher sent to vibrating screen by belt conveyor; 5.Oversized rock is back to fine jaw crusher for further crushing by belt conveyor; 6.Undersized materials sent to one transit ore bin by belt conveyor; 7.Fine ore in transit bin is sent to ball mill via electromagnetic vibrating feeder+belt conveyor. ball mill is to grind ore to powder size. 8.Discharge of ball mill goes to spiral classifier for roughly size separation. Coarse particles will be back to ball mill for further grinding; 9.Fine particles will be sent to the centrifugal concentrator for concentrating fine gold by a slurry pump. 10.Tailings of centrifugal concentrator go to sluice box for recovering more gold; 11.Concentrates of sluice box and centrifugal concentrator are sent to shaking table for fine concentrating gold. The ball mill + classifier forms a closed-circuit grinding system, which can achieve more than 90% of the discharge to 200 mesh(0.074mm) So this flowchart is very suitable for recovering fine powder gold in rocks.

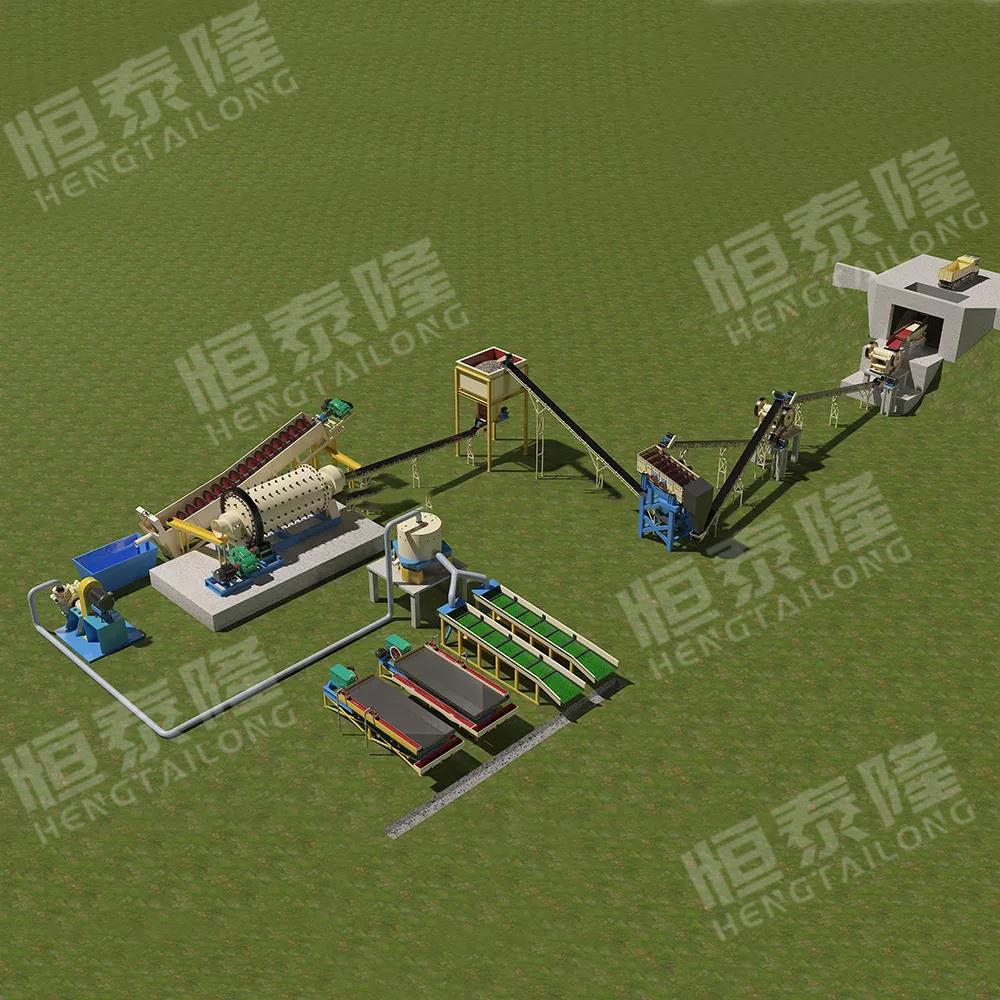

Widely Used Rock Gold Solution3:

Hard-Rock Gold Mining With Wet Pan Mill + Shaking Tables

1.Hopper+vibration feeder:Raw materials will feed into the hopper by truck or excavator as you want,then the materials will feeded into the jaw crusher by the vibration feeder automatically. 2.Jaw crusher:Jaw crusher is uesd to crush the rock gold ore, different model of the jaw crusher is with different input size,discharge size and capacity.the model of the jaw crusher is chosed based on the ore size and the capacity you want to process,big ore size need big model and more cost.3.Belt conveyor:Belt conveyor is used transport the discharge from the jaw crusher to the hopper,it works automatically, will save much manual work.and the length and width can be customized as you requested.4.Hopper+trough feeder:There are two functions of the hopper and trough feeder.5.Belt conveyor:Belt conveyor is used transport the discharge from the hopper to the hammer crusher,it works automatically,will save much manual work.And the length and width can be customized as you requested.6.Hammer crusher:Hammer crusher is used to small the discharge from the jaw crusher,because the feeding size of the wet pan mill is 0-25mm.The discharge from the jaw crusher hard to meet the needs of the wet pan mill.The hammer crusher can do work successfully, there is a sieve under the hammer crusher and the sieve size can be customized as you want, minimum sieve size can be 2mm,the smaller size you feed into the wet pan mill, the more efficent work you will get.7.Wet pan mill:For the rock gold ore, sometimes the gold can be released under the size 0-2mm or 0-1mm or 0-200mesh.These output size will need different machines and also depends on the ore condition.If you need to grind the ore to 0-1mm, you may need the wet pan mill.8.Shaking table:The shaking table is used to get the gold concentrate from the raw materials.When you add the water and materials to the shaking table, the gold will be separated from other stones and minerals which the gravity is lower than the gold.9.Gold smelting furnace:The gold concentrate from the shaking table can be smelted to the gold bar by the gold smelting furnace.Will easy to carry the gold and in case of missing.

Notes:The wet pan mill and shaking table will need water when works, you can also add water to the hammer crusher,in case blocking the sieve of the hammer crusher.the machines in the video are just for you reference, need to reconfirm based on the ore condition you provide.

Main Product

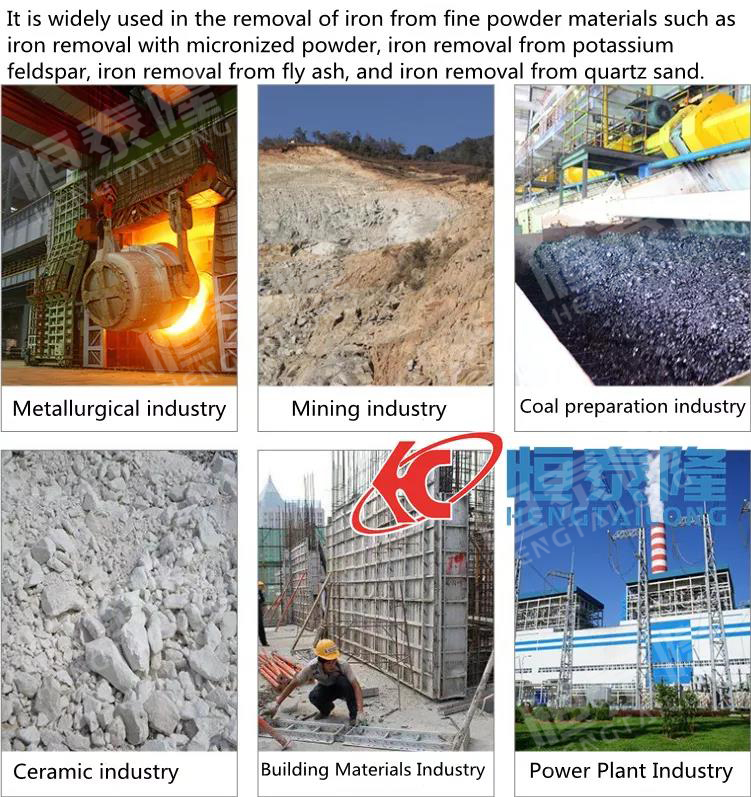

We have professional engineers team to draw flowchart based on customer's iron ore site details.

We supplied full set iron plant: vibrating feeder, jaw crusher, belt conveyor, cone crusher, double roll crusher, ball mill, spiral classifier, vibrating screen, magnetic separators.

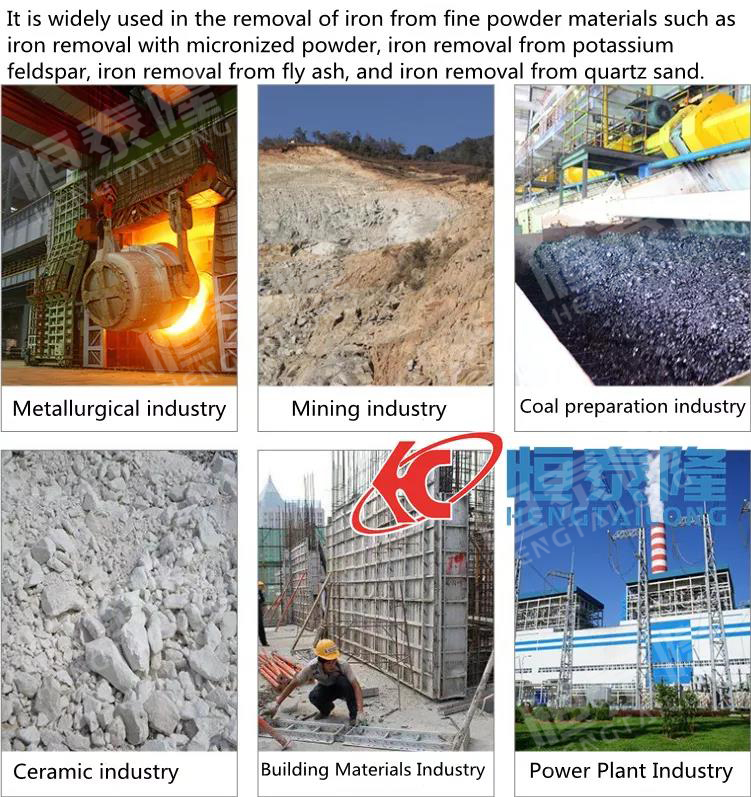

Product Application

It is mainly suitable for processing low sulfur oxidized minerals with a lot of sludge. Electrolytic extraction by desorption,carbon pickling and thermal regeneration, chemical preparation, wastewater treatment and gold smelting and other processes.

Raw Material

The carbon leach process is suitable for treating low sulfur oxidized ores with a lot of slurry, and is not suitable for high silver gold ores. Usually, the gold / silver ratio can not exceed 1: 5. At present, the best conditions for using the carbon leach method are: PH = 10-11, sodium cyanide concentration not less than 0.015% , size Activated carbon particle 1-3.35mm, the carbon type is coconut shell activated carbon, and the leach pulp concentration is 40-45%.

Working Principle

Gold extraction by carbon slurry’s characteristic is that fresh (or regenerated) activated carbon is added to the last adsorption tank, and the direction of movement of the carbon is opposite to that of the slurry. Finally, the gold-loaded carbon is extracted from the first adsorption tank, so it is called countercurrent adsorption of carbon.

From the front to the back of the carbon adsorption tank, the gold-containing grade of the solution gradually decreases, while the gold-loaded carbon that is picked up from the back tank gradually increases, and finally is raised by the first tank.

Since the desorbed carbon or fresh carbon after acid washing and thermal regeneration in this countercurrent adsorption method of carbon has the strongest activity and the fastest adsorption rate, it can minimize the final gold grade of the final tail liquid and reduce the amount of dissolved gold from the tail.

CIP Process

Mobile gold cip plant

1.After the crushing and grinding stage, add 9 step-arranged high-efficiency cyanidation leaching tanks into the pulp. Gold pulp cyanidation is carried on the first two leaching tanks, countercurrent adsorption operation is carried on the last six or seven leaching tanks (cyanidation and adding activated carbon simultaneously).

2.In the adding activated carbon step, add the coconut shell activated carbon (small hole, high activity, wear-resisting and renewable) specially selected by Xinhai mineral processing design institute into the pulp, which can dissolve and adsorb the gold and silver ions then form the gold loaded carbon according to the characteristics of gold and silver adsorption.

3.Vibrating screen and dewatering screen are the key equipment for the reverse movement of pulp and carbon. Filter press and high frequency dewatering screen developed by Xinhai can effectively reduce the carbon wear on the surface of vibrating screen and in the process of continuous slurry pumping, and reduce the cost, facipitate the maintenance and operation.

Air lifter used in the agitation process can make the slurry carry on small minor-cycle. Hengchang air lifter greatly reduces the power consumption by 70%, and make the solid materials suspend uniformly, the wear of activated carbon is small, and the recovery of gold is high, which is an important equipment in the modern gold cyanide plant.

4.Hengtailong desorption electrolysis system implements high-temperature desorption electrolysis on gold in the gold-loaded carbon through the mixed liquor of sodium cyanide and sodium hydroxide. After wood chips and other sundries are removed by washing machine, and the gold desorption is carried out by Xinhai high-temperature and high-pressure desorption method (150 degrees and 0.5Mpa), which can resolve 99% of gold within 2-6 hours.

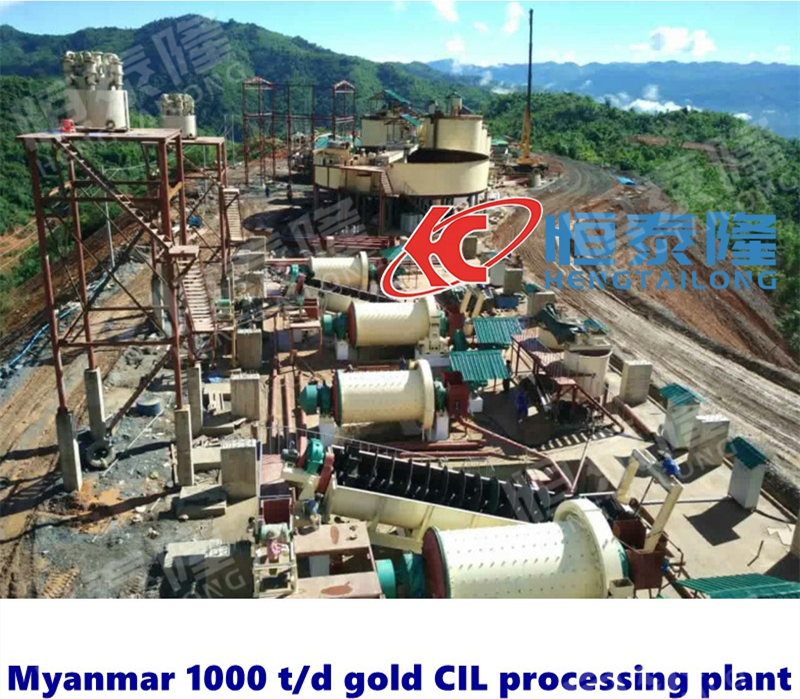

Crushing and Grinding system

In Gold CIP/CIL plant, to achieve high recovery rate, usually adopts double ball mill, one is grid type,

one is overflowed type, the grinding size will be 90%-200 mesh.

Leaching System

After the ore pulp adding cyanide, it will be pumped to leaching tank, usually we adopts 8 leaching tanks, installed in stair-stepping, the toppest two is preleaching tank,

will add actived carbon from lowest one, then use carbon lifting pump and carbon screen to lift the gold carried carbon one by one till highest.

After leaching, gold mud in grade about 30-40% will feed into electrolysis machine or melting furnace to separate gold and carbon, after this step,

the carbon can be recycled by acid and water washing tank. At last the gold grade will be at 98% above.

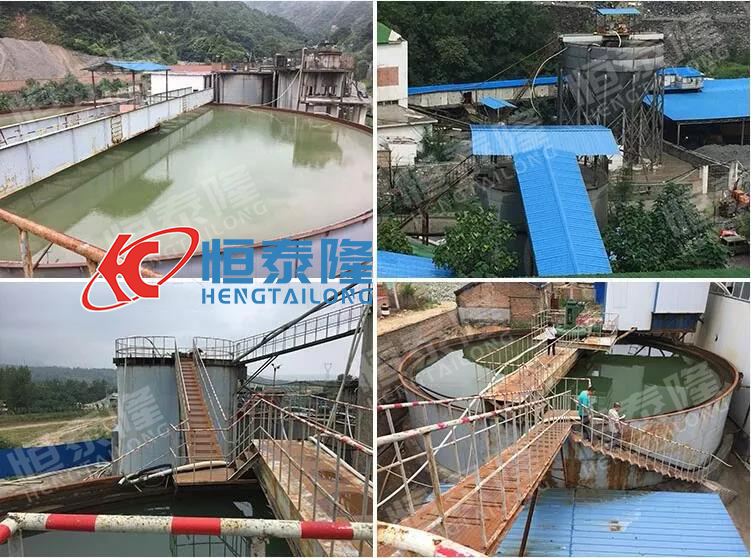

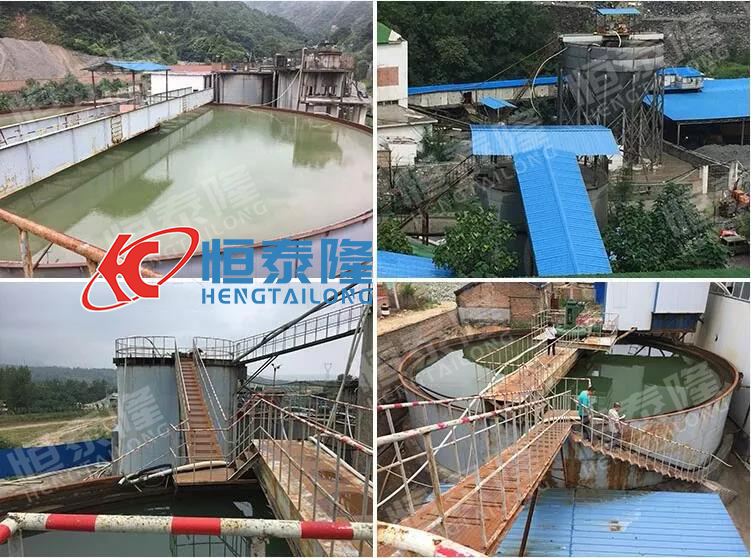

Thickening Syetem

After ball mill grinding, the ore pulp will be feed into thickner to dewater to achieve proper density to go next step leaching.

Under the thickner, there is enough space to build several warehouse and install a chemical mix tank.