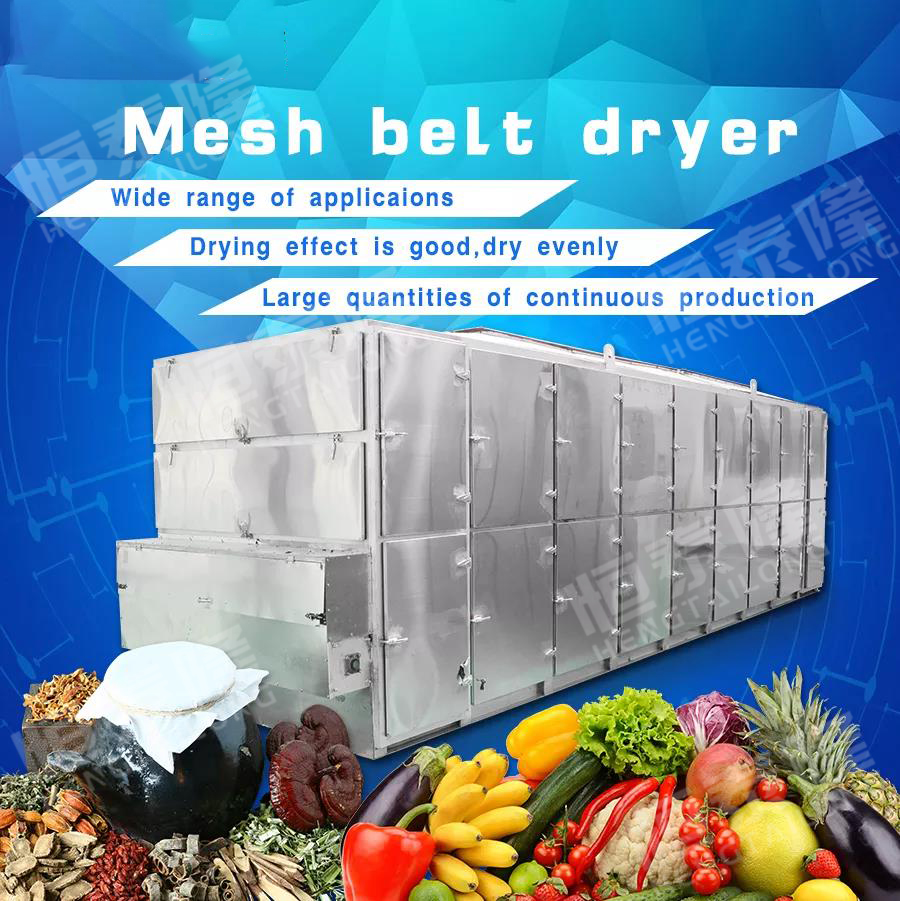

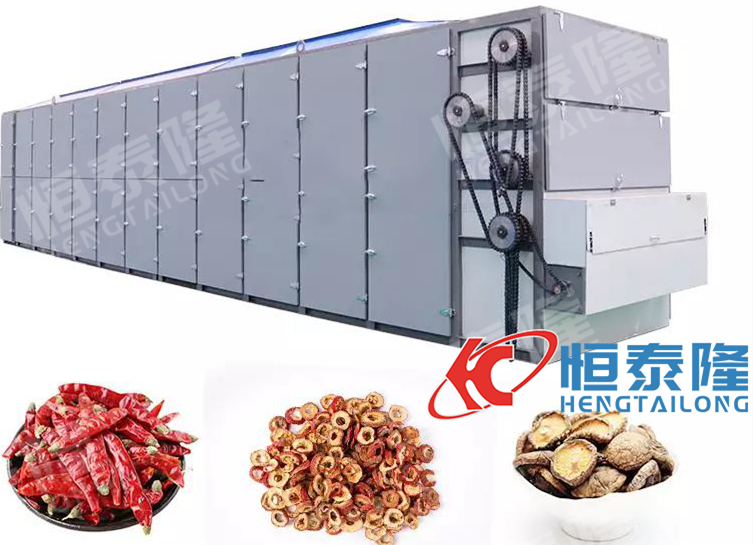

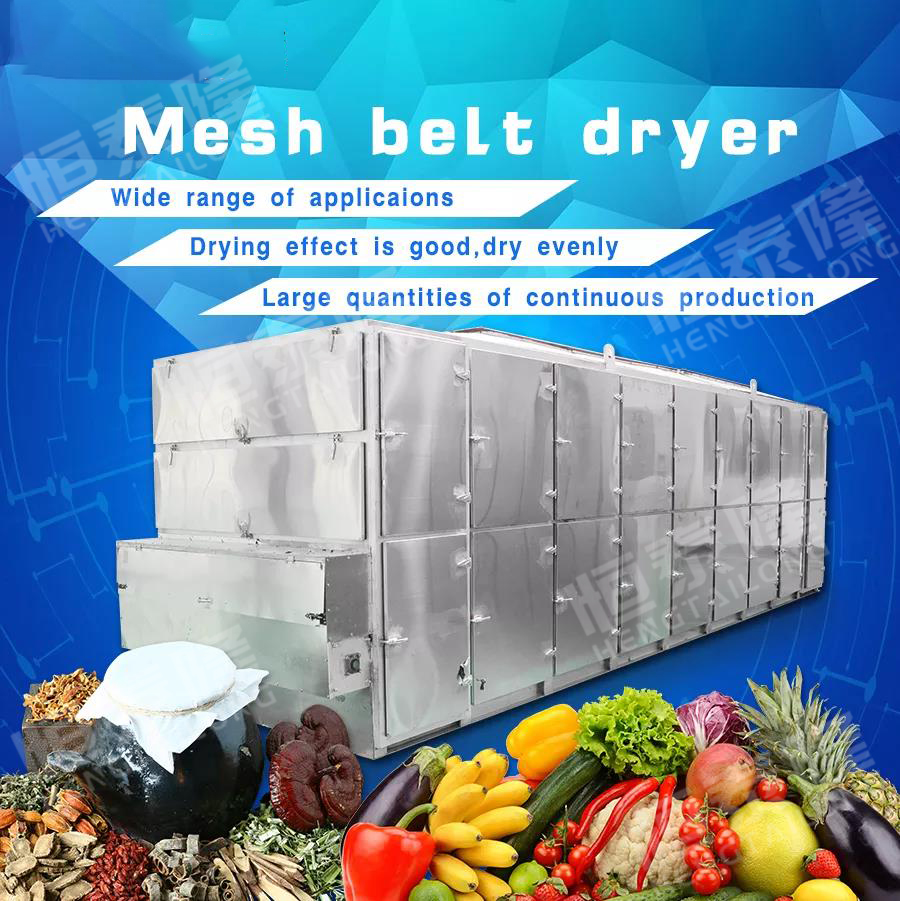

Multi-Layer Mesh Belt Drying Machine Vegetable and Fruit Mesh Conveyor

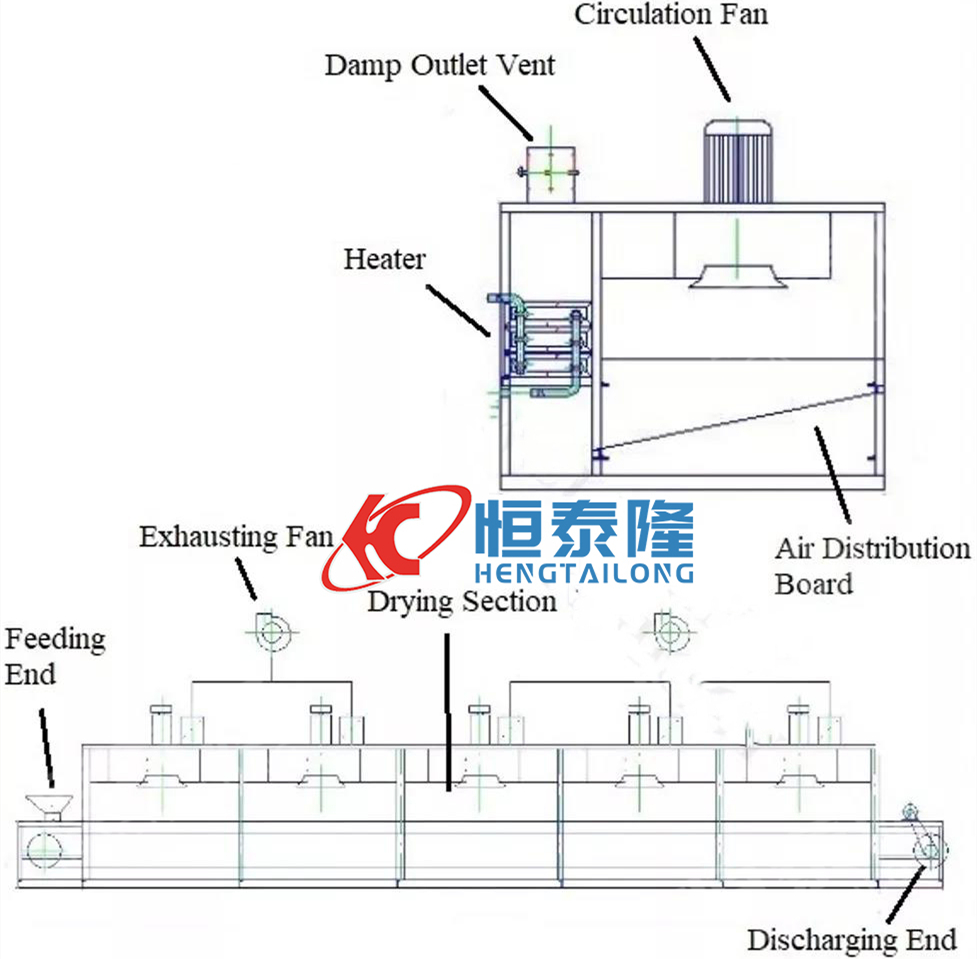

The material is evenly spread on the mesh belt by the feeder, and the mesh belt is generally made of 12-60 mesh stainless steel wire mesh,which is dragged by the transmission device to move in the dryer. The dryer consists of several units, each unit circulates the hot air independently, part of the exhaust gas is discharged by a special dehumidifying fan, and the exhaust gas is controlled by a regulating valve. The process of mass transfer takes away the moisture of the material. The mesh belt moves slowly, and the running speed can be freely adjusted according to the material temperature, and the dried finished product continuously falls into the receiver. The upper and lower circulation units can be flexibly equipped according to user needs, and the number of units can also be selected according to needs.

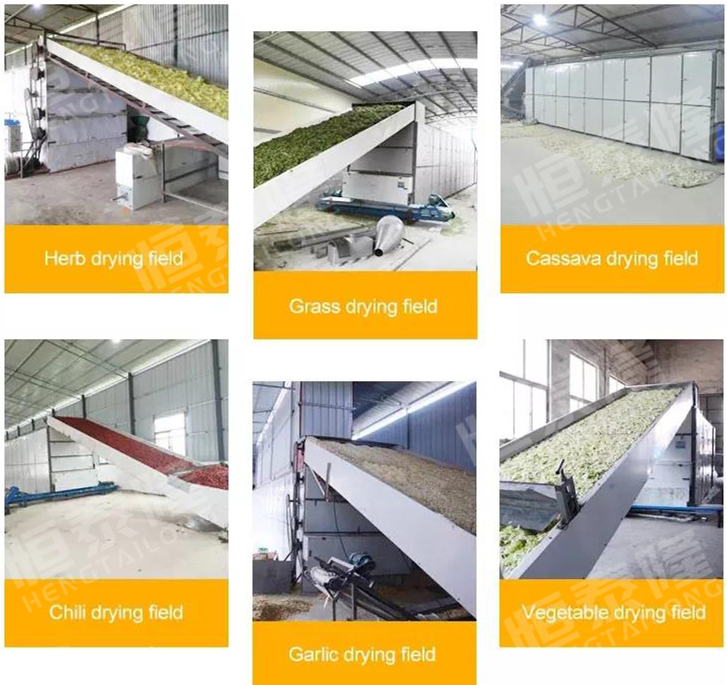

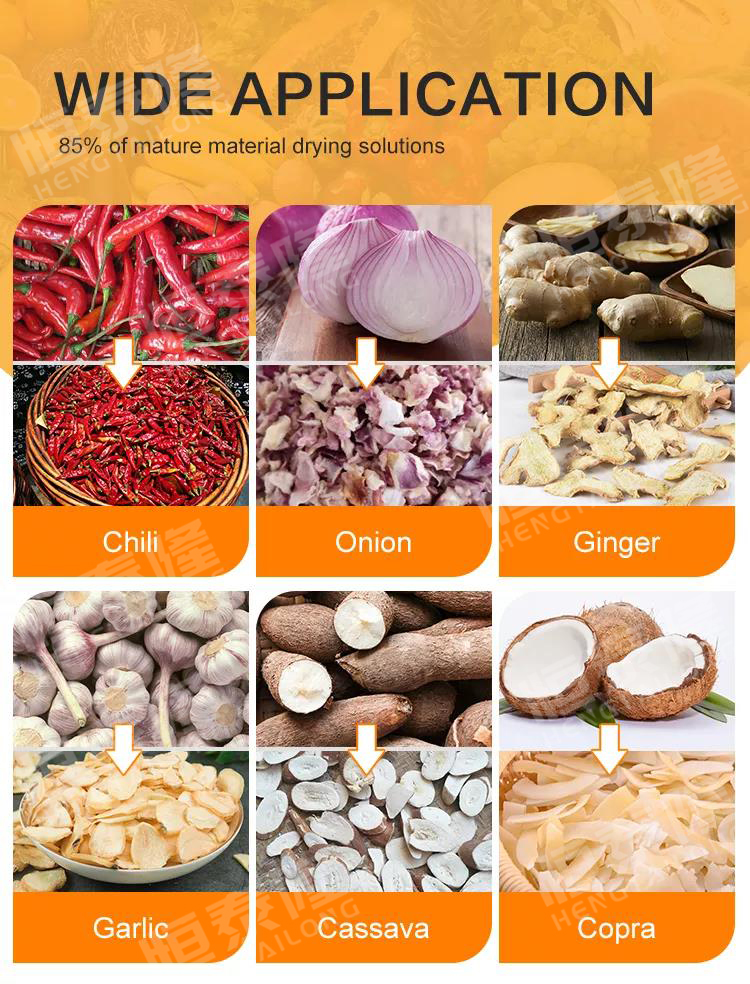

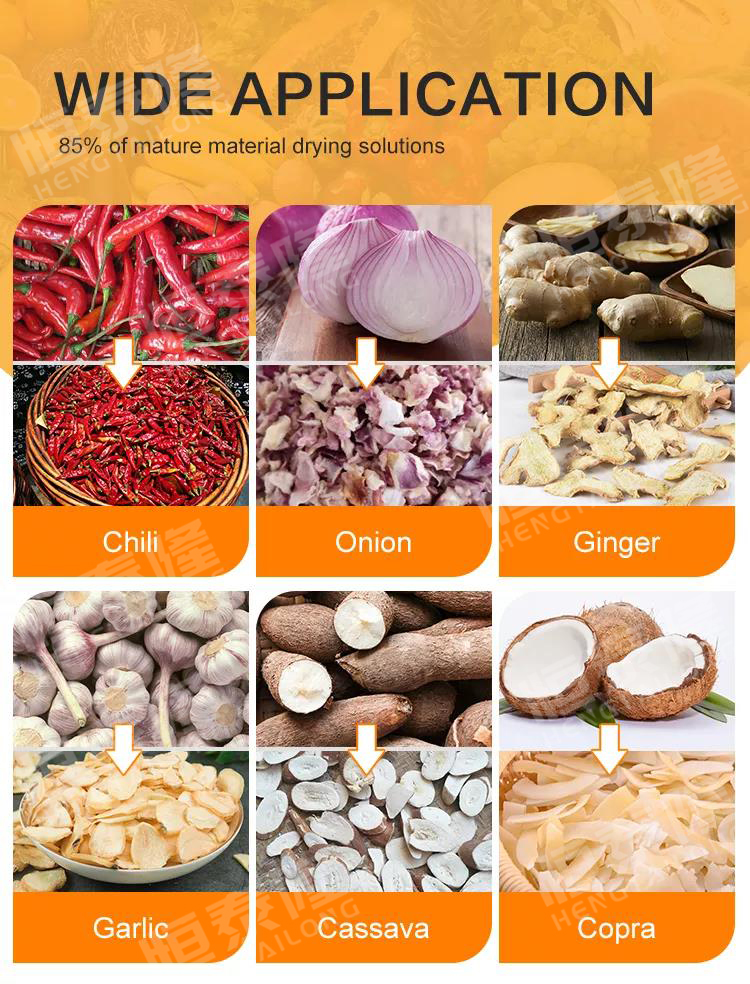

Product Applications

Fruit:Almonds, jujube, peanuts, longans, walnut, papaya tablets, apple, lemon, hawthorn pills, bananas, etc.

Vegetable:Asparagus, beans, kidney beans, lentils, eggplant, red pepper, Chinese prickly ash, black fungus, tremella, papaya

tablets, pills, bitter melon, radish, cucumber slices, mushrooms, ginger, garlic, etc.

Medicinal material:Flos lonicerae, radix scutellariae, salvia miltiorrhiza, burdock, fructus schisandrae, codonopsis, radix rehmanniae,

prepared rhizome of rehmannia, mulberries, forsythia, Chinese wolfberry, etc.

Others:Lily, rose, peony seed,fennel seeds,et...

Product Advantage

▲.Appropriate operating conditions can be set, and operations such as temperature and air volume can be adjusted according to the corresponding drying state of the ventilation mode condition.

▲.Freely adjust the moisture content after processing, because the material stop flow and residence time in the drying device can be adjusted freely, This sets the moisture content of the processed product.

▲.The shape and dust are rarely damaged. The material moves in a static state in the drying device, which can hardly damage the product shape, and no dust is scattered.

▲.Various conveyor belts can be used. Depending on the dry material, in addition to various wire meshes, the conveyor belt can also be vibrated. moving plate.

▲.The conveyor belt can be cleaned, and the heating chamber is separated from the drying chamber, which is convenient for cleaning the conveyor belt.

▲.On request. A cleaning device can be installed on the bottom plate of the equipment to scrape a small amount of material dropped on the bottom plate to the discharge end.

▲.According to the different moisture content of the output material, multiple equipments can be selected to be used in series to increase the output.

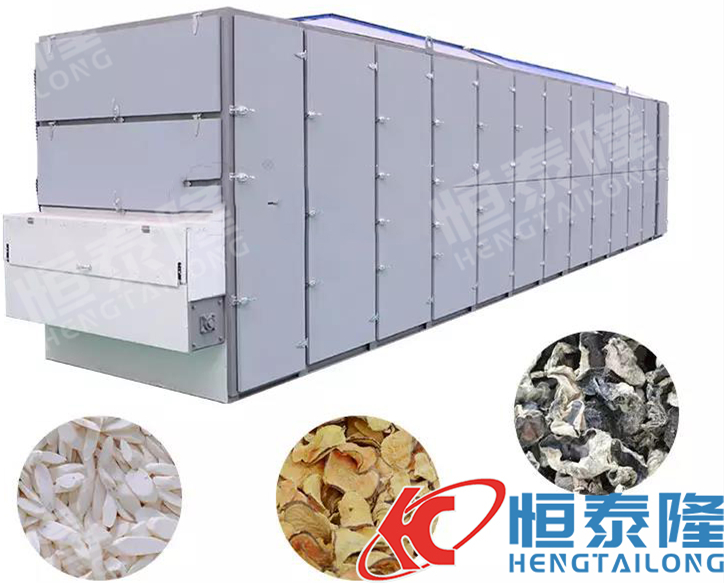

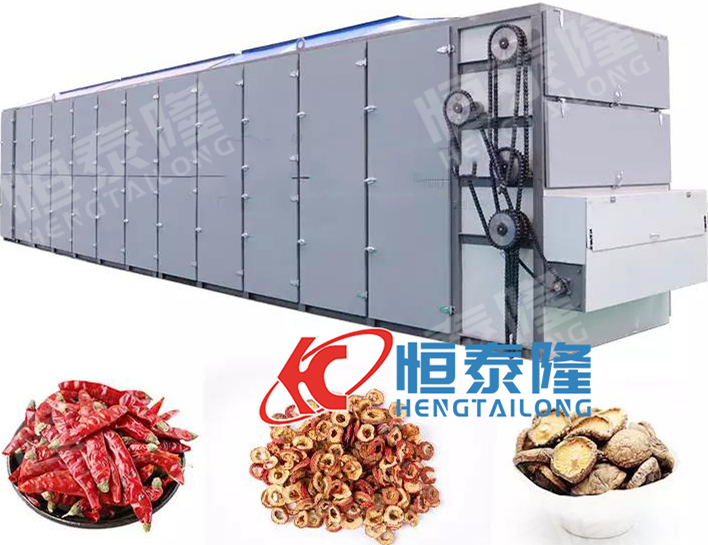

Product Details

Large conveying capacity

There are few requirements for material types, and goods can be transported in large quantities, saving labor costs, saving time and effort.

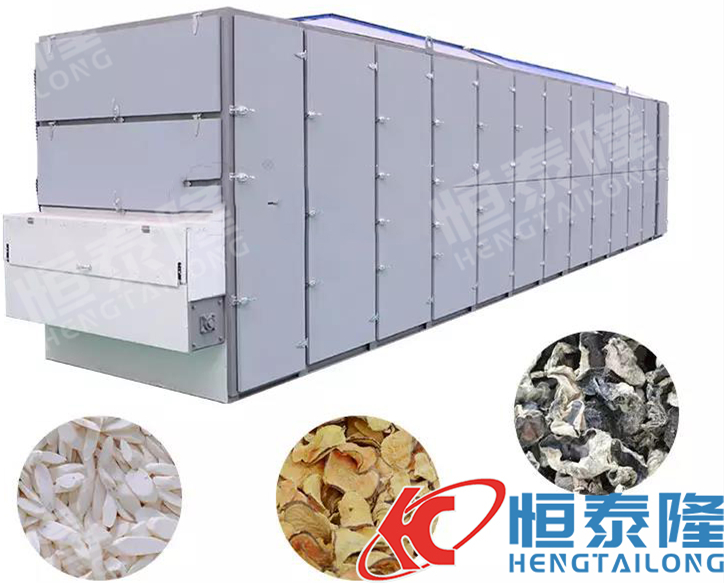

Stable delivery

Conveyed by stainless steel mesh belt, high strength and low flexibility.

Multi-layer drying

Using multi-layer drying design, drying at the same time, high work efficiency.

Temperature adjustable

Free temperature control, adjustable and controllable.

Optional motor

According to the weight of the product to be conveyed, the motor is optional, and the speed is adjustable.

Integrated process

Integrate the production process, and can arrange a variety of stations in the assembly line to meet the needs of production operations.

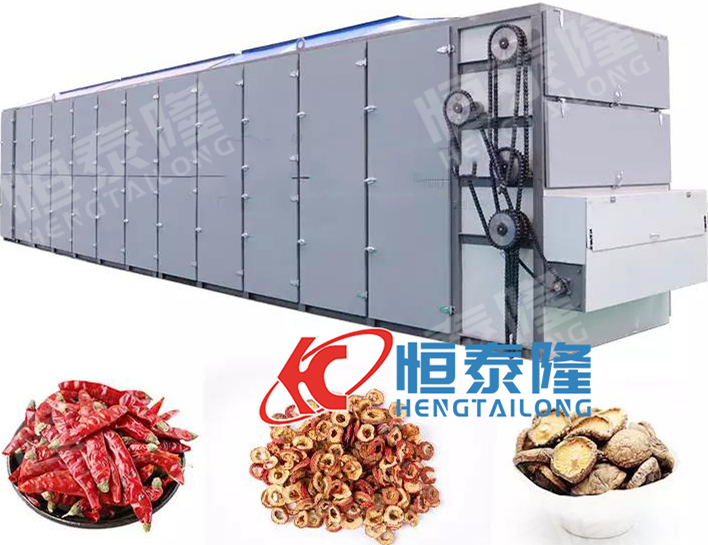

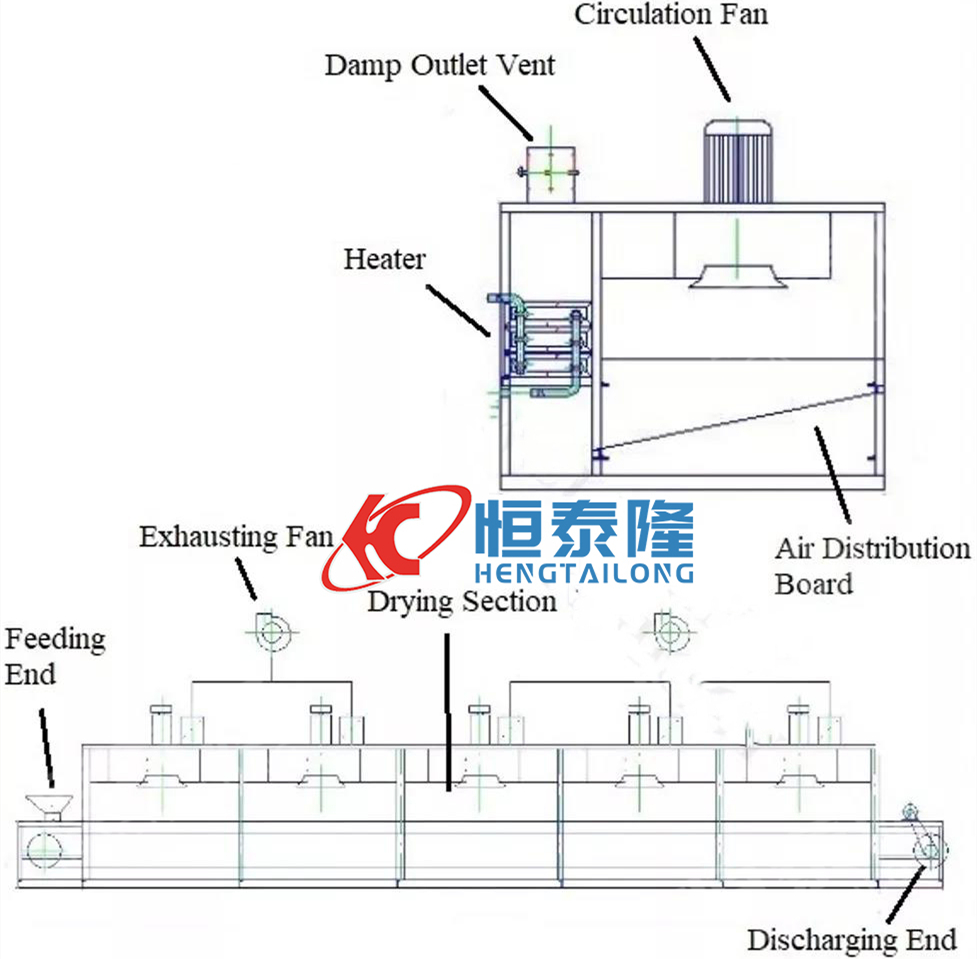

Working Principle

The materials are uniformly put on the mesh-belt by the feeder. The mesh-belt uses generally 12-60 mesh stainless steel wire net and it is drawn and moved inside the drier by a transmission device.

The drier is composed of several units. For each unit, the hot air is circulated separately. Some exhausted gas is discharged with a special moisture elimination blower.

The waste gas is controlled through an adjustment valve. The hot air passes through the mesh-belt covered with the material from the top to the bottom or from the bottom to the top and this will complete the heat and mass transfer process. This process will bring the material water away.

Do you have this trouble?

When you need to dry a lot of materials every day, you need intelligent and automated drying machines.

However, the dryers on the market have poor drying effects, high energy consumption, and still require a lot of manual operation.

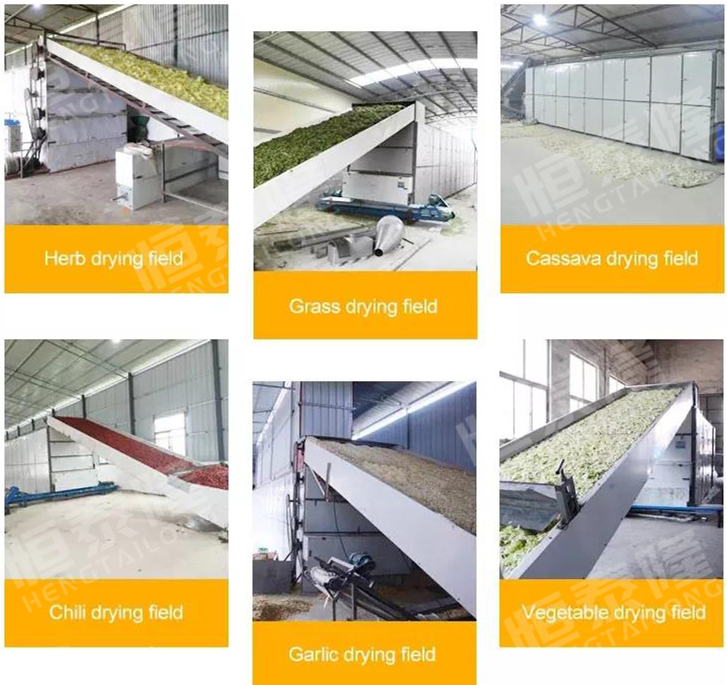

This greatly affects your production management. Hengtailong automatic industrial conveyor belt dryer can help you.

Hengtailong belt dryer with a large capacity for daily processing and can reach dozens of tons a day by multiple-machine.

Use medium temperature drying, which improve product quality and market competitiveness. Hengtailong belt dryer can be directly connected to the back-end equipment for the next process.

Only one person is required for handle the whole system from feeding to output.

Hengtailong belt dryer is an ideal automatic production equipment, which can not only improve your brand awareness, but also make production management more standardized.

What can it dry? We have been helping various food industries with our accurately crafted Hengtailong factory outlet tunnel conveyor mesh belt dryer for fruits and vegetables Automatic Dryer, such as:

> Dried fruit production plants,

> Pet food production lines,

> Meat processing lines,

> Potato processing lines,

> Green peas processing lines,

> Cassava flour production lines,

> Packed food industry.

If your drying project is not on the above list, we will be all too glad to offer guidance, design, and manufacture of a customized drying system. Just tell us your requirements!