Alluvial Tantalum Gold Ore Processing Trommel Gold Mining Wash Machine

The mobile gold trommel is a kind of gold equipment which can be moved on land. It has the characteristics of compact structure, strong integrity, light weight, large handling capacity, simple operation, reliable operation, easy maintenance and convenient operation.We has been exported to Sudan, Africa,North Korea, Tanzania, Ghana etc. The main structure of the GTS trommel gold wash plant is a screening cylinder, which is composed of several circular meshes and also inclined with the ground; outside is sealed by the sealing guard to prevent environmental pollution;Through variable speed deceleration system, the screening cylinder is rotated at a certain rotation speed, and the material is separated from the top to the bottom through the screening cylinder, the fine material is discharged from the lower part of the front end of the screening cylinder. The drum screen can be provided with a comb-shaped cleaning mechanism, and the relative movement of the comb-shaped cleaning mechanism and the screening cylinder can be achieved the effect of cleaning the sieve body without ant interruption during the screening process, so that the sieve and the splitting cylinder is always clear and does not affect the screening effect throughout the working process.

Product Applications

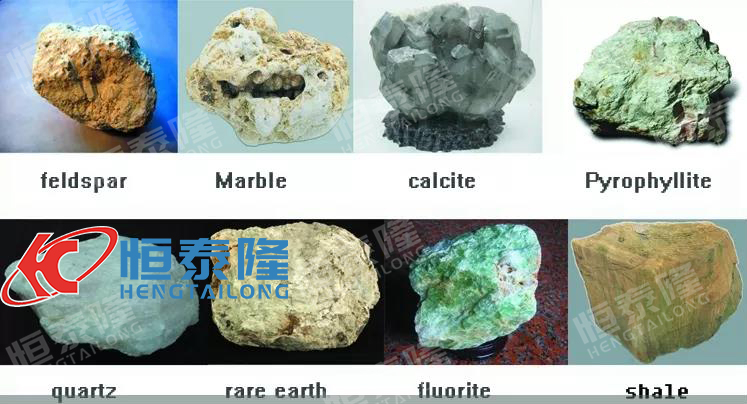

Mobile gold trommel machine is widely used in gravity concentration og gold, diamond, tin, barite, tungten,placer gold, hematite ore,manganese,titanium, antimony, lead, tantalum, niobium and other minerals.Timber and composting industrial, municipal solid waste industrial, food and chemical industrial, coal, ore or mining industrial, C & D waste industrial.

Product Details

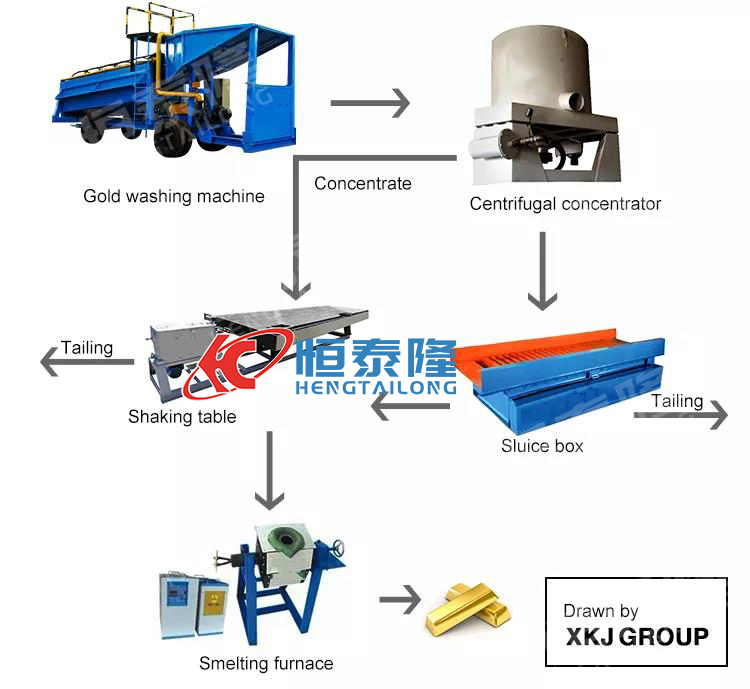

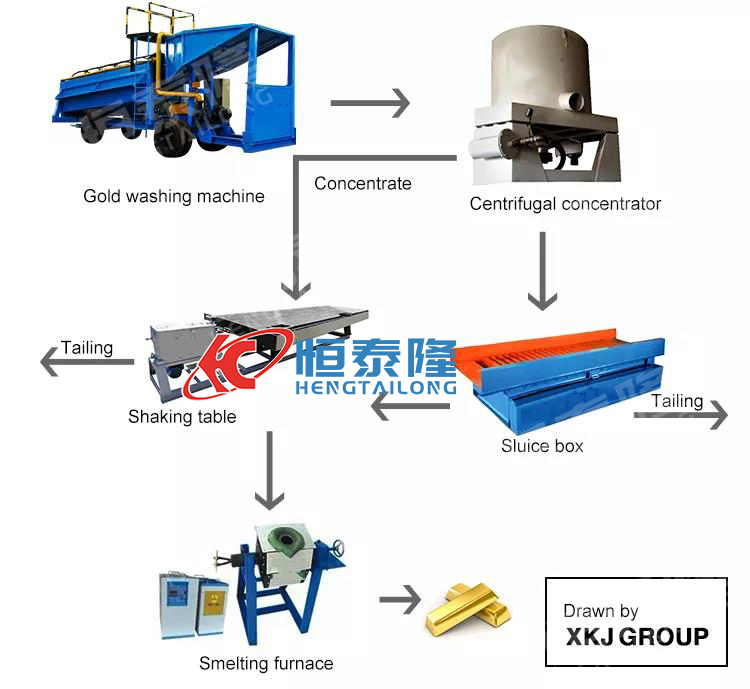

The gold drum screen provides a simple, efficient and economical solution to upgrade a wide rang of material and optimize the subsequent process steps of recovery. This method of screening helps to reduce operating and investment cost and to increase product quality, while allowing rapid and large volume processing.Trommel screens are constructed of high quality material, designed for high performance, high Production rates, lower operating costs and lower maintenance.This material is then passed on to the downstream process equipment which can be in various formsSuch as centrifugal Concentrator, spirals, jigs etc;

Working Principle

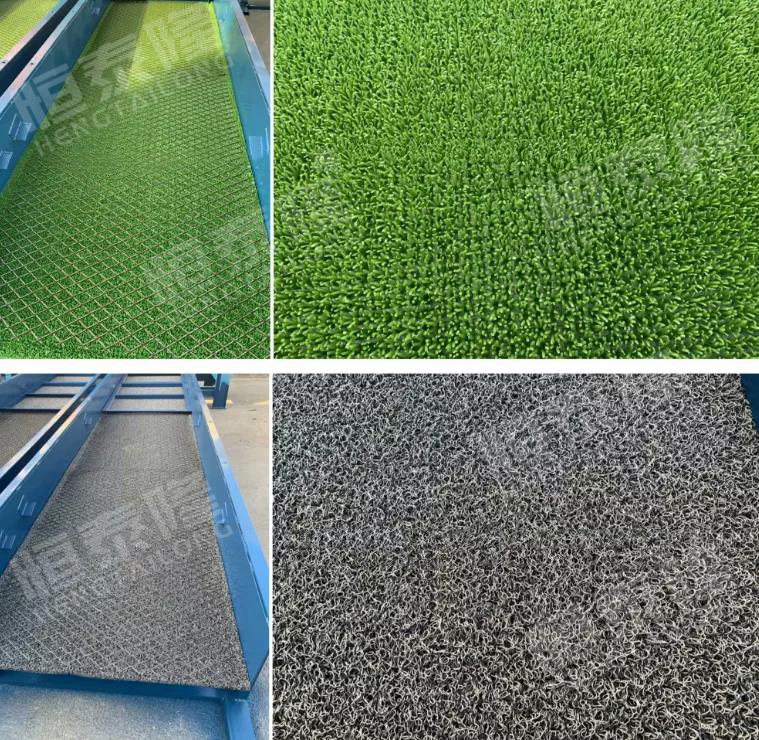

Material feed into the hopper by excavator,high pressure water released and wash the mineral,then,mineral by forward into the drum.It is lifted up by the rotation and aerated as it fall back down.This finer material passes through the screen openings while the large material tumbles towards its eventually exit at the real of the drum.After that,the final mineral and water go through the sluice bow which is consist with gold grass mat.The no use mineral are washed out and the gold are catched by the gold grass mat.

Product Advantages

Includes water pump, water pipe, diesel engine / electric motor, wheel, can be easy movable.Mobile with wheels, can free transport/move to other lace when finish the job. It is suit to small scale / large mine processing.

1.Diesel engine / electric motor, can work in no power field.2.Bigger hopper, single / double layer screen designed.3.Water pump with water pipe release high pressure water.4.It is popular in African, Asian, South American due to its easy to move and easy to operate.5.It is low cost, miner just cost a little budget to buy one. Many miner came to our factory to buy it for their alluvial gold, river sand mineral, diamond mining.

Gold Sluice Box Features

1.Low price: compare to other machines, the price of sluice box is very very low. 2.High efficiency: With two types of carpet, no matter the gold granule is in big size or small size, it's will be caught by the sluice box.

3.Easy to install and operate: With a light weight, and small size, this equipment could be installed by hand, and the operation is very easy,after a certain time of feeding material, wash the concentrate inside the carpet, and then you can put the carpet back and continue the work.4.Easy for maintenance: The only part need to service or change is the carpet, and the carpet is in a high quality, so the service and maintenance is easy.5.Large capacity: A sluice box with 1000*6000MM could processing over 8 tons crudes for one hour. we can customized the dimension as your request.6.No power consumption: The sluice box no needs any power, which makes the operation very convenient.

Related Products

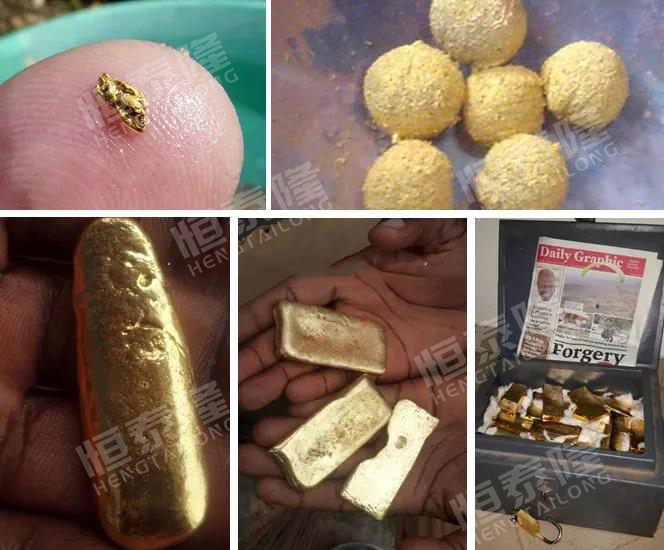

This equipment is designed for processing alluvial gold mine, river sand gold, placer gold, diamond etc.