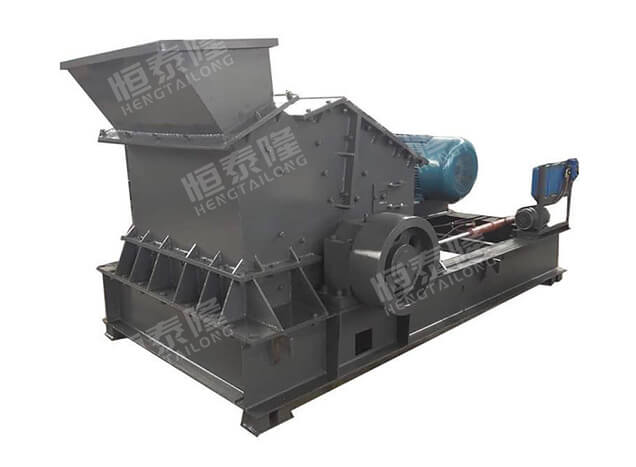

Impact fine crusher

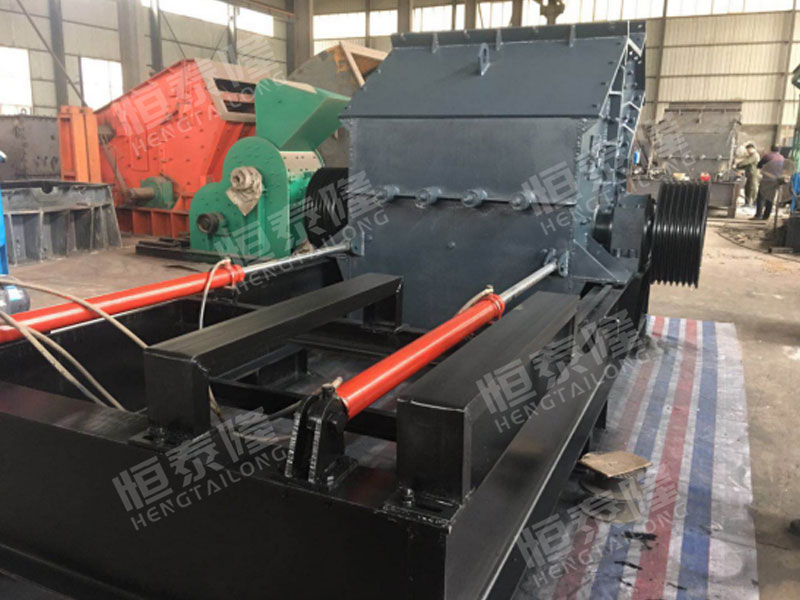

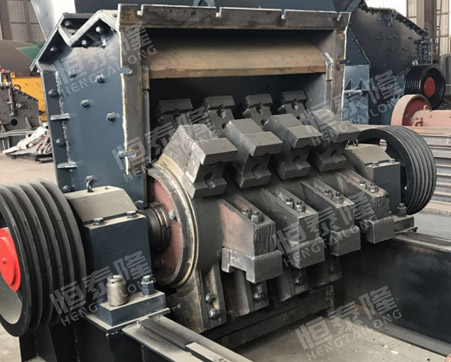

[Product Brief]: PCX series high efficiency impact fine crusher is a new generation of high efficiency fine crusher. Using a reasonable combination of multi-chamber crushing chambers, a new type of convenient dual adjustment mechanism, can ensure that the discharge particle size ≤ 3mm occupies 85%, and the product size is fine and uniform.

[Feed size]: 0-190mm

[output size]:0-5mm

[Production capacity]: 20-300t/h

[Scope of application]: Metallurgical, chemical, building materials, electric power, transportation and other industrial sectors.