gold mining iron zinc silver copper ore manganese separating froth flotation cell tank machine

The flotation machine is suitable for the separation of non-ferrous and ferrous metals, as well as for the separation of non-metals such as coal fluorite and talc.

The SF flotation machine is driven by the V-belt drive of the motor to rotate the impeller, which produces a centrifugal effect to form negative pressure.

On the one hand, it sucks in sufficient air to mix with the slurry, on the other hand, it stirs the slurry and the medicine, and at the same time refines the foam,

so that the mineral is bound to the foam.Float to the pulp surface and then form mineralized foam. Adjust the height of the gate to control the liquid level,

so that the useful foam is scraped out by the scraper.

Product Details

The flotation machine is mainly used for sorting non-ferrous metals such as copper, zinc, lead nickel and gold, and can also

be used for rough selection and selection of ferrous and non-metal. The motor is driven by the motors V-belt drive to rotate the impeller,

which generates centrifugal force to form a negative pressure On the one hand, it absorbs sufficient air to mix with the slurry.

On the one hand, it mixes the slurry with the drug, and refines the foam to make the mineral bond foam mineralized foam is

formed on the slurry surface. Adjust the height of the shutter and control the liquid level so that the useful foam is scraped off by the scraper.

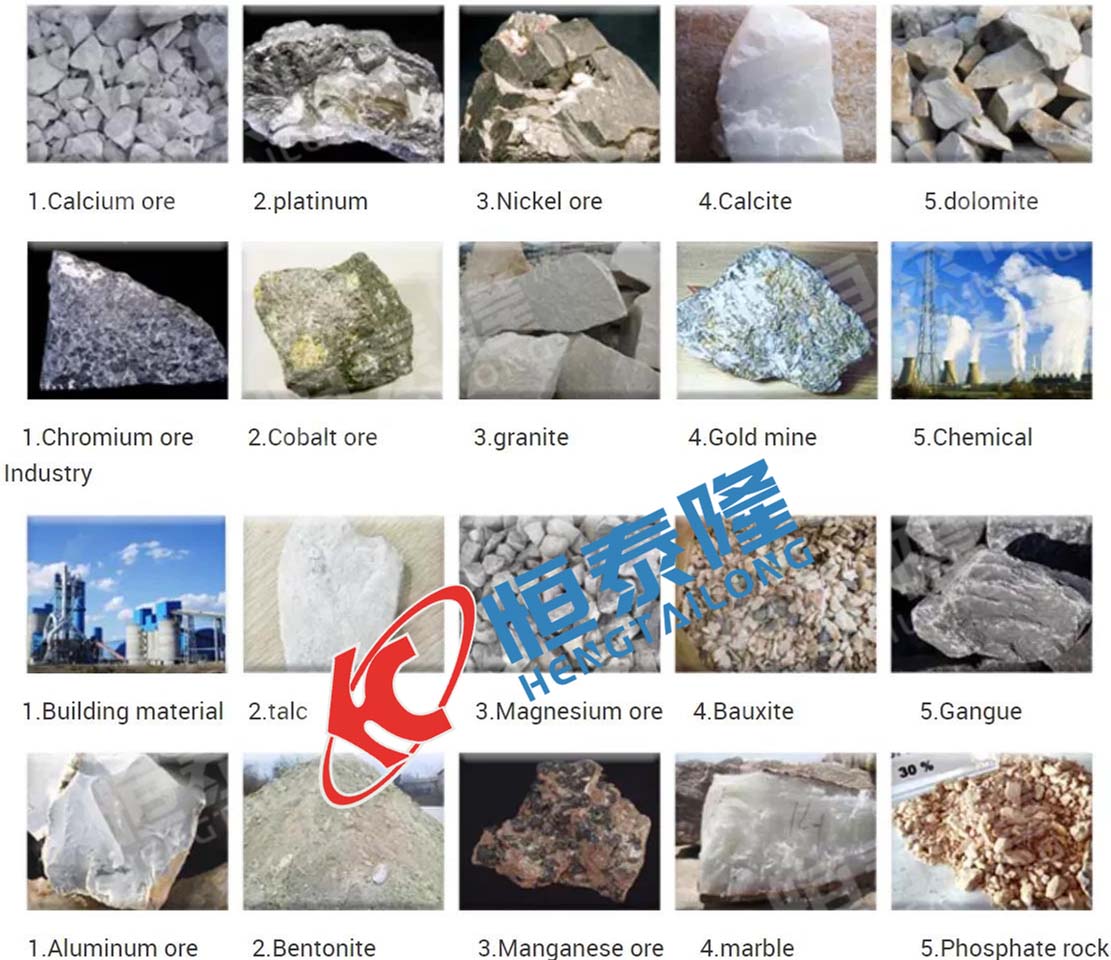

Product Applications

The flotation machine is mainly used for sorting non-ferrous metals such as copper, zinc, lead nickel and gold, and can also be used for rough selection

and selection of ferrous and non-metal. The motor is driven by the motors V-belt drive to rotate the impeller, which generates centrifugal force to form a

negative pressure on the one hand, it absorbs sufficient air to mix with the slurry. On the one hand, it mixes the slurry with the drug,

and refines the foam to make the mineral bond foam Mineralized foam is formed on the slurry surface. Adjust the height of the shutter and

control the liquid level so that the useful foam is scraped off by the scraper.

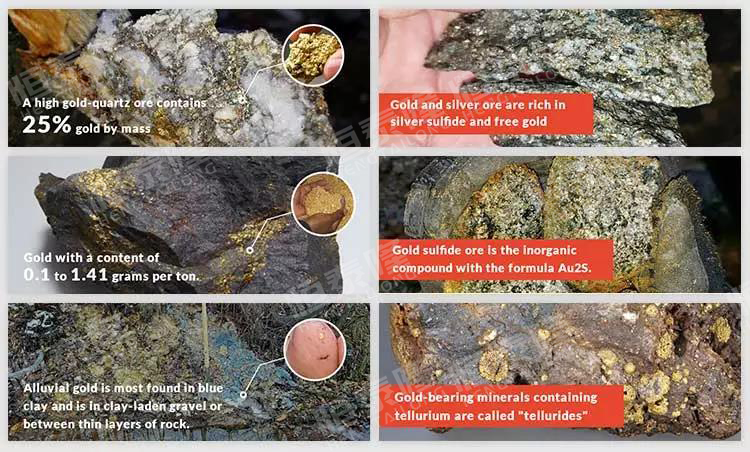

6 types of gold ore

Gold exists in quartzite. Usually, quartz appears as small stones in large cracks in riverbeds or mountain slopes and has crystals in different colors such as white,

yellow, pink, purple, gray, or black. The most common types of quartz with gold ore are rose quartz gold ore and rainbow gold ore.

A high gold-quartz ore contains 25% gold by mass, and it occurs in areas where the bedrock is fractured by tectonic and volcanic activity.

According to different physical and chemical properties of different types of gold ores, flotation separation utilizes various reagents to make the gold attached

to the bubbles then scraping these gold particles from blades to get the concentrate.

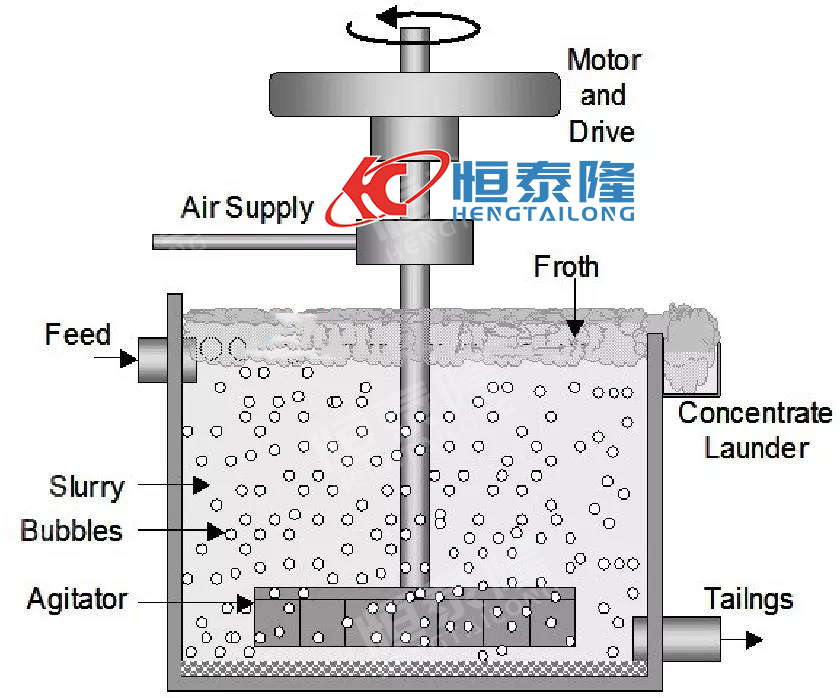

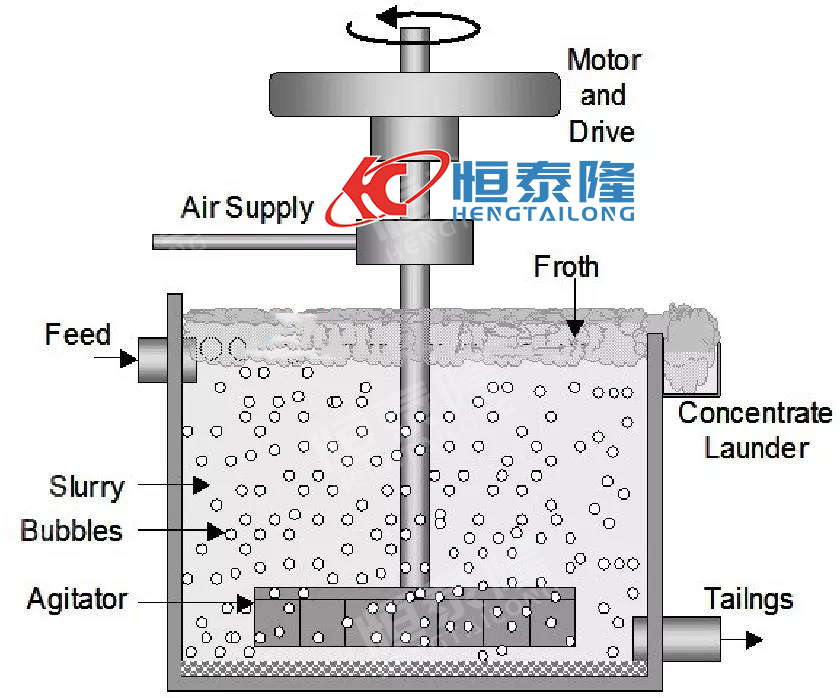

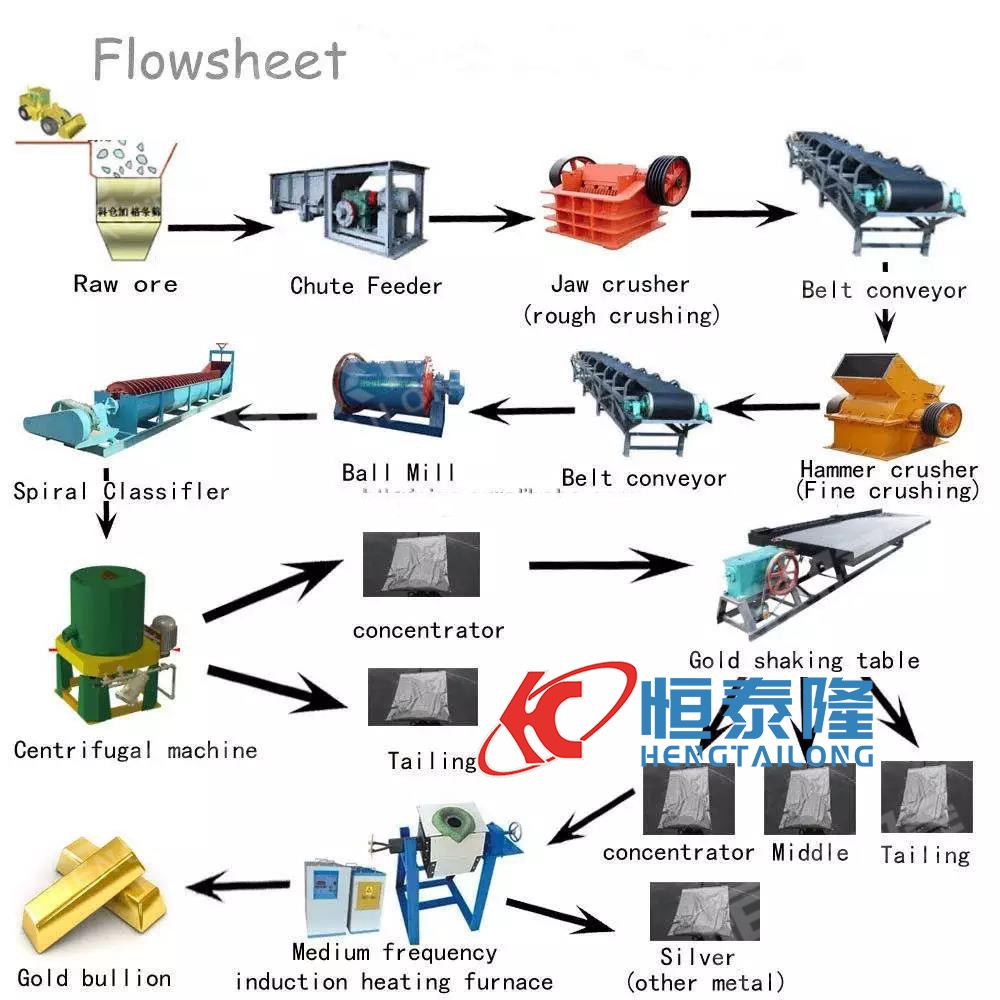

Working Principle

The impeller is rotated by V-belt of motor and produces negative pressure by centrifugal function.

Enough air is sucked to mix slurry, and slurry mixes drug at the same time.

Mineral sticks on bubble completely and floats on the surface of slurry to form mineralized bubble.

Useful bubble is scraped out by adjusting flashboard height and controlling liquid surface.

One or more gas chambers are installed in the bottom of the tub, on the cover of the gas chamber are full of one-way valves.

When the one-way valves are open, the pressed air will be fed into the flotation cell.

Product Advantages

(1) large capacity;

(2) low energy consumption;

(3) Every cell owns three functions:air absorption,slurry absorption,and flotation separation,and the cells form a flotation separation loop by itself without

any auxiliary equipment and is allocated horizontally,which favors the change of flow;

(4) The circulation of mineral slurry is reasonable,and can avoid the disposition of coarse sand to the largest extent;

(5) There is a self-control device on the surface of mineral slurry,so it is easy to adjust it.

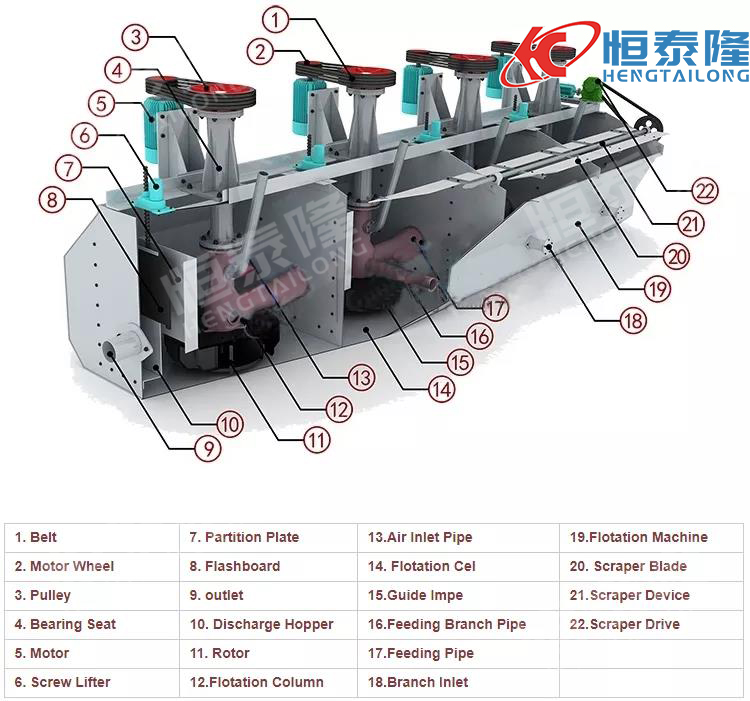

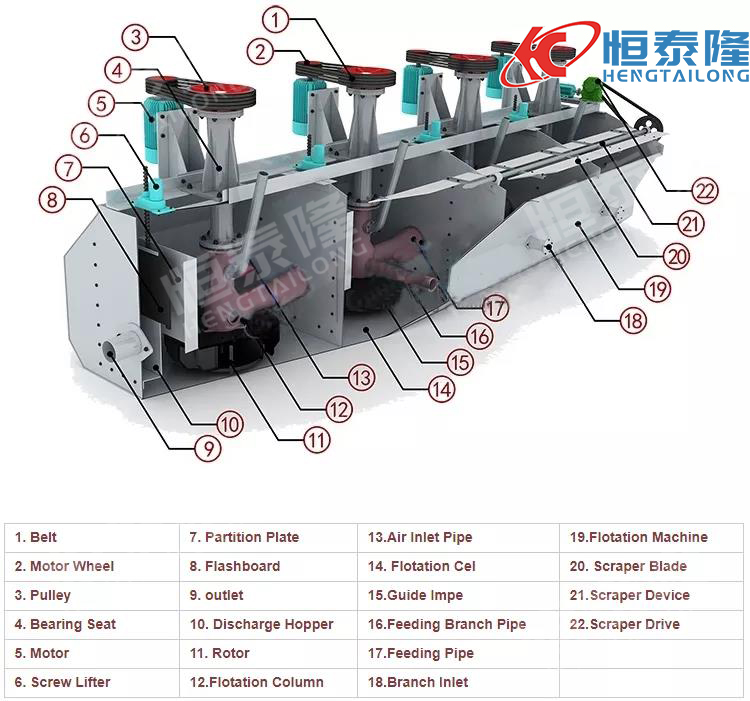

Product Structure

Flotation machine is mainly composed of tank body, impeller, stator, dispersing cover, false low, draft tube, vertical tube, adjusting ring.

Shallow tank, small diameter, low rotary speed, and low power consumption.

Large clearance between impeller and stator, the stator is a cylinder with elliptic hole, and it is good for mixing and dispersing the gas and pulp.

The height of stator is lower than impeller, pulp circulation volume is large, and it can be reached at 2.5 times of others.

The umbrella-type dispersion cover with holes of the stator can separate the eddy current and bubbles that produced by impeller,so as to keep the pulp surface stable.

.jpg)