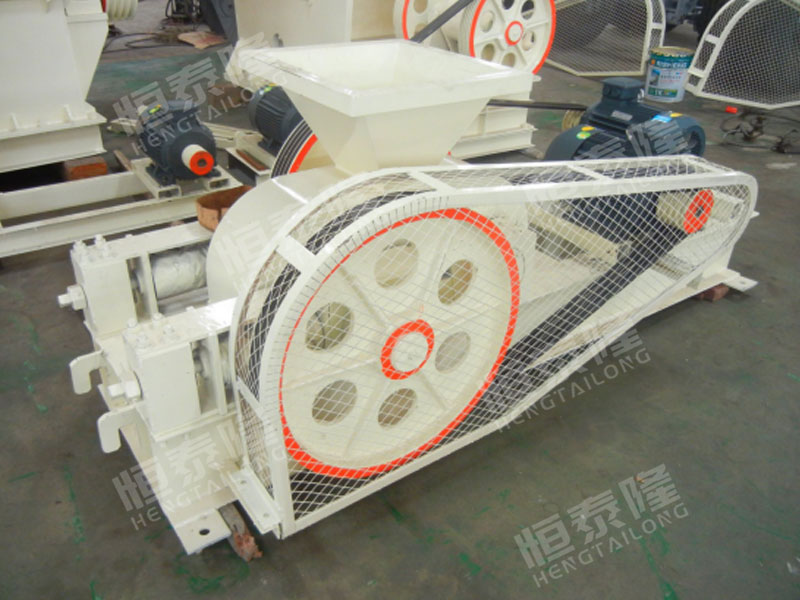

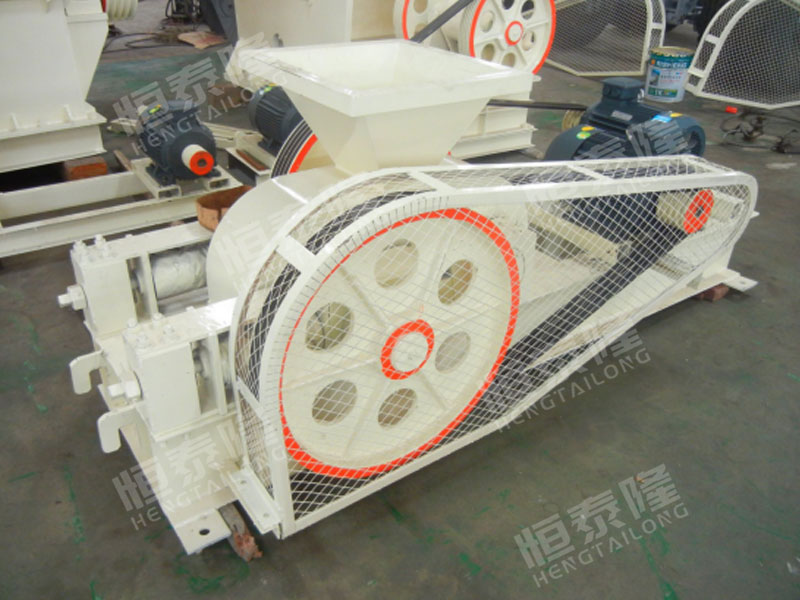

The roller crusher can be divided into double roller or multi roller crusher according to the number of rollers. The double-roller crusher is the most common crusher. It is suitable for coarse and intermediate crushing of brittle bulk materials in industries such as cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines, etc., with large particle size and discharge The granularity is adjustable, and it can crush materials with compressive strength ≤160MPa. Especially in the coal industry, using this machine to crush raw coal.

As long as it is iron-removing, impurity-removing, and gangue-free, it can be directly crushed. The crushed materials have uniform particle size and low crushing rate, which simplifies the coal preparation process and reduces investment and production costs.

Working principle:

Double roller crusher mainly composed of fixed and movable crushing roller, pressing and adjusting device and driving device.The working mechanism is two cylindrical rollers.A roller is supported by a fixed bearing and a roller is supported by a movable bearing.The electric motor drives the two rollers to rotate relative to each other.The material is crushed by the friction of the two rotating rollers, and the broken material is discharged from the two rollers by gravity.The spring is sufficient to balance the pressure between the two rollers.If there is a non-crushing falling into the two rollers, can push the bearing compression spring to create a large gap to make the non-crushing thing through, after the non-crushing thing through, the spring can make the gap between the two rollers to maintain the original size, continue to work.

Feature:

-

1Equipped with a roller crusher in the mineral grinding production line, the grinding equipment can give full play to its production capacity, generally increasing the output by 30%-40% and reducing the total energy consumption by 20%-30%.

-

2Compact structure, light weight, small size, for the same production capacity of large requirements of the grinding system, the equipment of the roller crusher can significantly save investment.

-

3Simple structure, small space, convenient operation and maintenance.

-

4It is equipped with dust proof plate, with good sealing performance, which can avoid the spatter of small materials after crushing, with less dust, low working noise and better working environment.

-

5The weight of the abrasive roller is newly optimized, the equipment does not need to change the mill roller for life, while the old roller machine needs to be dismantled for overhaul and replaced after being used for one year.

-

6The roller crusher is equipped with a replaceable wear-resistant lining plate. The wear-resistant lining plate is made of domestic advanced wear-resistant materials, which has the advantages of long service life, not easy to damage and convenient maintenance.The continuous service life can reach more than one year, if the wear is serious, remove the boot cover can be replaced.The maintenance quantity is small, the cost is low, this is any other type of domestic crusher is incomparable.

-

7The roll crusher is equipped with safety protection device. When an unexpected metal iron piece enters the crushing chamber, the protection device will move and the iron piece leakage device will operate normally.

-

8The gap of the abrasive body of the roll crusher can be adjusted arbitrarily between 1mm and 20mm. After the gap is adjusted according to the requirements of the crushing particle size, the crushing particle size can be controlled reliably, and all of them can be discharged under the crushing chamber with the ideal particle size.

-

9Simple and reasonable structure, low operating cost, smooth operation, high efficiency and energy saving, high crushing efficiency, adjustable discharging particle size.

-

10Roller crusher is the working principle of low speed and high pressure roller extrusion.The material from the upper part of the crusher falls vertically into the crushing chamber. Under the pressure of crushing caused by the strong pressure generated between the two rollers, most of the material has become powdery, and a large number of cracks have been generated in the interior of the remaining part of the granular material.In the course of further crushing, the grinding energy consumption can be greatly reduced and the output can be increased.

Advantages:

-

Smooth roller

-

High strength steel manufacturing, suitable for sand and stone production line, non-metal ore grinding line. Roller long life, can be widely used in all kinds of ore stone.

-

Tooth roller

-

High strength steel manufacturing, suitable for coal gangue and other light viscosity, humidity materials.