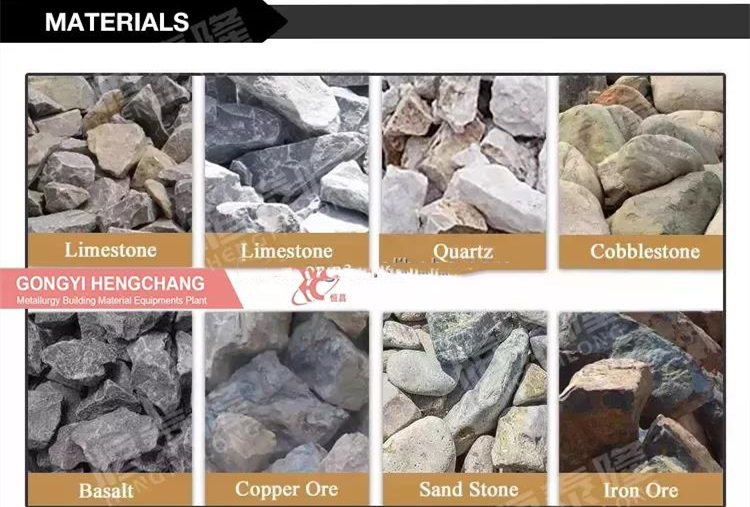

hot sale mineral mining mineral quartz mine iron ore processing spiral classifier machine

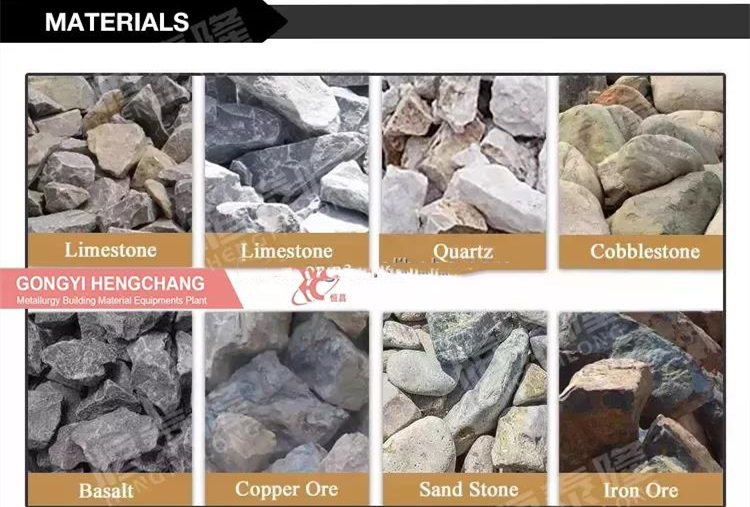

Spiral classifier is one of the classifying equipment in mineral processing. It is suitable for classifying materials in the mineral processing plant as well as the desliming and dehydrating in the mineral washing operating process and widely applied to separate the particles into a number of products graded according to size in the complete closed loop together with ball mill in the mining industry.

It is widely applied to the mining industry, such as separating light particles from heavy particles in the gravity separation process, separating fine particles and liquid from coarse particles in the metal ore processing, and separating the slurry or liquid from solid particles in ore processing plant.

Product Details

1.Low energy consumption: with the same processing capacity, the energy consumption is reduced by 50% compared with other horizontal and vertical classifiers.

2.High efficiency: with the same processing capacity, the classification efficiency is 50% higher than that of other horizontal and vertical classifiers.

3.High precision: high grade fineness, completely eliminate the oversized particles and screen residue in the product.

4.High output: the output of large machine can reach 50t / h.

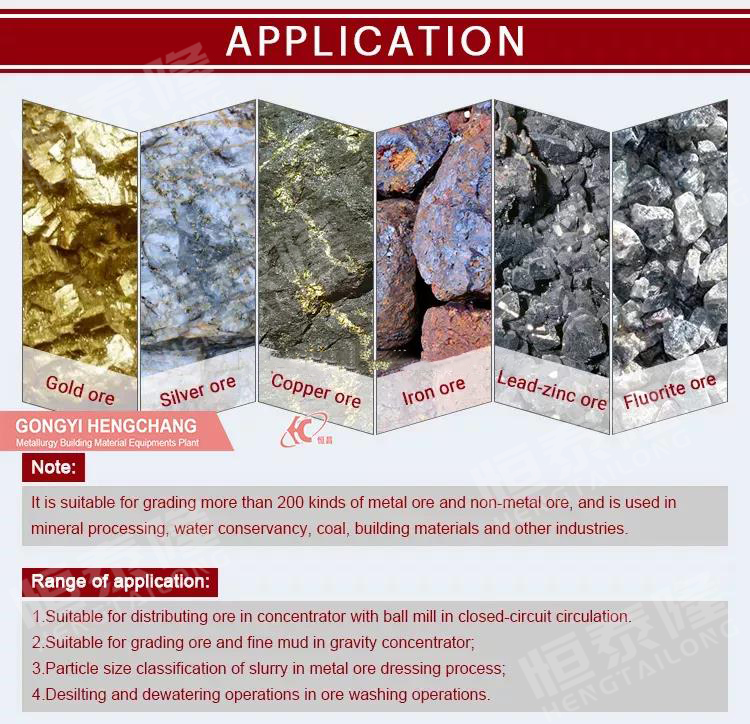

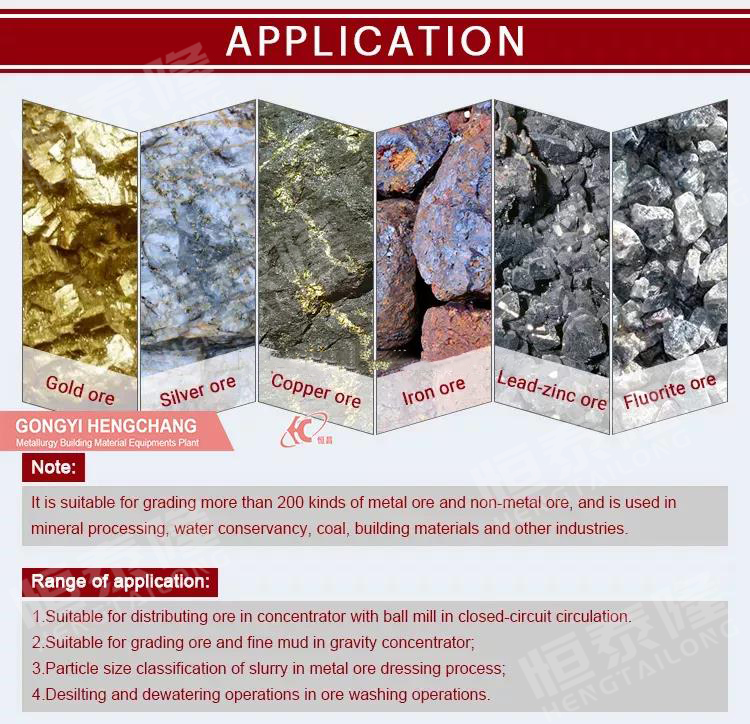

Product Application

It is widely applied to the construction industry, such as separating light particles from heavy particles in the gravity separation process,

separating fine particles and liquid from coarse particles in the metal ore processing, and separating the slurry or liquid from solid particles in ore processing plant.

Working Principle

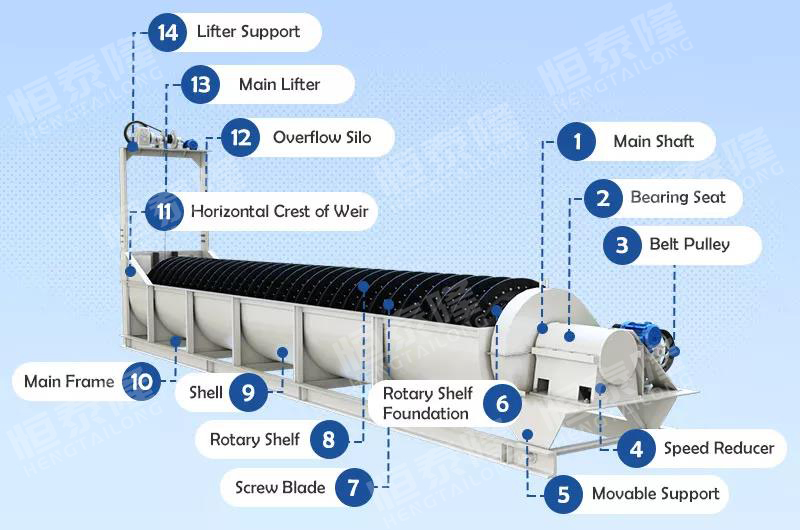

The slurry is fed into the U-shaped groove from the feed inlet in the middle of the side of the channel. With the low speed rotation of the screw and continuous stirring of the slurry, most light and fine particles are suspended on the top, and overflow from the overflow Weir becomes the overflow product.

Coarse and heavy particles will settle at the bottom of the trough (sand sink, pushed by the spiral blade above the chute and discharged,

and dehydrated simultaneously during the transportation process. If the sand sinking through the chute into the grinding machine regrinding, the sand into the grinding machine is sand return.

Sand Washing Plant

The Sand Washing Plant can class the finely milled materials by particle size, fine particles suspended in the water become into the overflow outflow, coarse particles sink to bottom,

by the screw pushing into the upper and return to grinding machine, the machine is also used to separate fine clay in the minerals and used for ores dehydration.

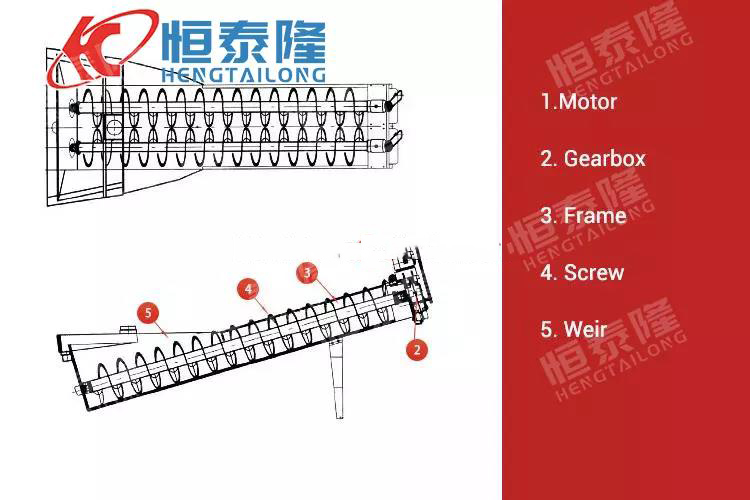

Spiral: It is the main components of this machine, it formed by the main shaft, frame, spiral blades, lining iron frame.

The frame, spiral blades, linked iron are formed to connected spiral surface, because the shaft is constantly rotating, so the role of helical face is mixing the slurry ,

make fine particles flow from the overflow weir, coarse mineral particles conveyor from the screw first to discharge port.